What is Pipeline Pigging and Why It's Important

Pipelines transport various materials including oil, gas, water, and chemicals over long distances. Over time, pipelines accumulate deposits of sediment, scale, and other contaminants. The buildup of these deposits reduces a pipeline’s efficiency and increases its risk of corrosion and failure.

Pipelines transport various materials including oil, gas, water, and chemicals over long distances. Over time, pipelines accumulate deposits of sediment, scale, and other contaminants. The buildup of these deposits reduces a pipeline’s efficiency and increases its risk of corrosion and failure.

The term, “pipeline pigging,” derives directly from the pig-shaped devices designed to move through the pipeline as they clean and inspect the interior walls. “Pigs” are inserted into a pipeline through existing openings. They are propelled by the flow of the material carried by the pipeline or, in some cases, by an external energy source.

Pigs

Can be made of various materials and different designs, all based on the task they are performing.

The history of this technology dates to the early 20th century when pigs were first used to clean sections of natural gas pipelines in the United States. Through the years, smart pigging has advanced to include various types of pigs for an assortment of specific purposes. In recent years tracking and data collection systems used to monitor pipeline conditions have exponentially improved.

The following information offers an explanation of pipeline pigging and its relevance to efficient pipeline maintenance.

What Is Pigging?

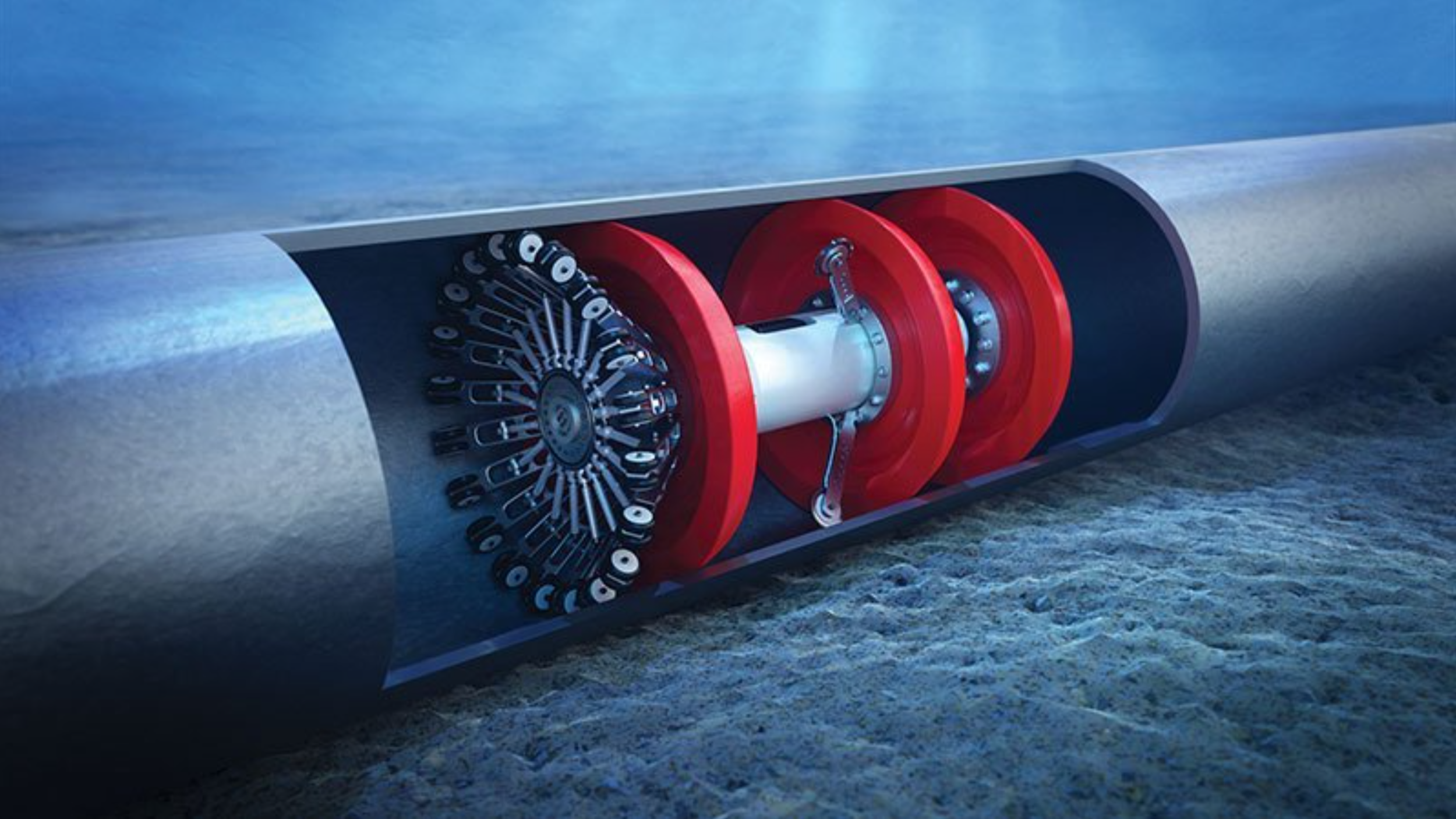

Pigging is a maintenance technique where a projectile-like device called a pig is inserted into a pipeline to perform tasks such as cleaning, separating products, or inspecting the pipe's internal condition. The pig is typically made of foam, rubber, or urethane and may contain brushes, discs, or advanced sensors.

Originally developed for cleaning oil and gas pipelines, pigging has evolved into an advanced technology used across various industries, including food and beverage, pharmaceuticals, chemicals, and personal care. Pigging is also referred to as line pigging, pipeline pigging, or product recovery pigging, depending on the industry and purpose.

What is Pipeline Pigging?

The process of pipeline pigging involves inserting a “pig” into a pipeline for cleaning and inspection. The “pig” is a cylindrical or spherical-shaped tool made from a variety of materials such as rubber, polyurethane, steel, or even ice!

Several types of pigs are used in this process.

Cleaning pigs are designed to remove debris, scale, and other deposits that can accumulate in a pipeline. They typically are equipped with brushes or other scraping devices to clean the interior of the pipeline as they move.

Inspection pigs do exactly what the name implies. They inspect the pipeline interior for defects such as cracks, corrosion, or other damage. Sensors within the pig collect data and images used to assess the condition of the pipeline.

Batching pigs separate different types of materials in a pipeline. For example, in a pipeline carrying oil, batching pigs can be used to separate the grades thus preventing contamination.

Gauging pigs measure the diameter and thickness of a pipeline. They often contain magnetic or ultrasonic sensors that detect changes in wall thickness. Such changes can indicate areas of corrosion or damage.

Regardless of type, pigs are propelled through the pipeline either by the flow of the material being carried or by an external energy source such as compressed air or water. As they move through the pipeline, the pigs clean or inspect the interior while collecting and transmitting data to monitoring systems for analysis.

Pipeline Experts: Inspection, Cleaning, Coating & More

Certified solutions for inspection, pre-commissioning, cleaning, internal coating, ice pigging™, mapping, and turnkey pipeline projects—maximizing safety and reliability at every stage.

How Does Pipeline Pigging Work?

The pig is launched into the pipeline through a pig launcher and is pushed along the line by the pressure of the fluid, compressed air, nitrogen, or even the next batch of product. As the pig travels through the line, it performs its designated function—whether it’s cleaning, gauging, or inspecting the pipe. Once it reaches the end of the line, it is collected in a pig receiver.

To ensure full coverage and effectiveness, pigs are often tracked using transmitters (TX) and receivers (RX), geophones, or other sensor-based devices. These tracking systems confirm that the pig has passed through key pipeline segments and help detect if it becomes stuck or encounters resistance.

Why is Pipeline Pigging Important for Efficient Pipeline Maintenance?

Pigging contributes to the cost-efficiency and overall effectiveness of pipeline maintenance. By removing sediment, debris, and other contaminants from the interior of the pipeline, this process improves the flow of material and reduces the risk of costly blockages. Pigging also helps extend pipeline life by preventing corrosion and other damage.

Without regular maintenance, pipelines can become clogged or damaged, leading to costly shutdowns and repairs. Using pipeline pigging, operators can identify and address issues before major problems occur. This substantially reduces the need for unplanned downtime and expensive repairs.

Damaged pipelines can cause leaks or spills leading to environmental contamination. Pigging reduces these hazards by helping keep pipelines clean and in good working order.

Pipeline pigging is essential to effective pipeline maintenance. By using pigs to clean and inspect pipelines, operators can reduce the risk of downtime, extend the life of pipelines, and prevent environmental damage.

Types of Pipeline Pigs

As a pigging service provider, we utilize a range of specialized pigs—each selected for your pipeline’s specific needs. Our team determines the right type of pig for each project, whether the goal is cleaning, inspection, or product recovery. Common pig types we deploy include:

1. Cleaning Pigs

These pigs are designed to remove dirt, wax, scale, and biofilm. They may include brushes, discs, or blades to scrape and push debris forward.

2. Inspection Pigs (Smart Pigs)

These high-tech pigs are equipped with sensors to detect corrosion, cracks, dents, or changes in pipe wall thickness. They use technologies such as Magnetic Flux Leakage (MFL) or Ultrasonic Testing (UT).

3. Batching Pigs

Used to separate different products in a pipeline (e.g., between two grades of oil or chemicals) to prevent contamination.

4. Gauging Pigs

Often used before the first run of a smart pig, gauges pigs check for pipe bore obstructions and deformation.

5. Product Recovery Pigs

Common in food and sanitary industries, these pigs reclaim residual product left in the pipe, helping companies improve yield and reduce waste.

Why Is Pigging Important?

Regular pigging helps:

Maintain Optimal Flow Rates: By clearing debris and buildup.

Prevent Corrosion: By removing moisture and contaminants.

Detect Early Defects: Reducing the risk of costly failures.

Extend Pipeline Lifespan: By supporting preventive maintenance.

Enhance Environmental Safety: By reducing leaks and product waste.

Pigging is essential not just for oil and gas pipelines but also for hygienic and sanitary applications. For example, food-grade systems use pigs to recover product left in the line and reduce water and cleaning agent usage.

Components of a Pigging System

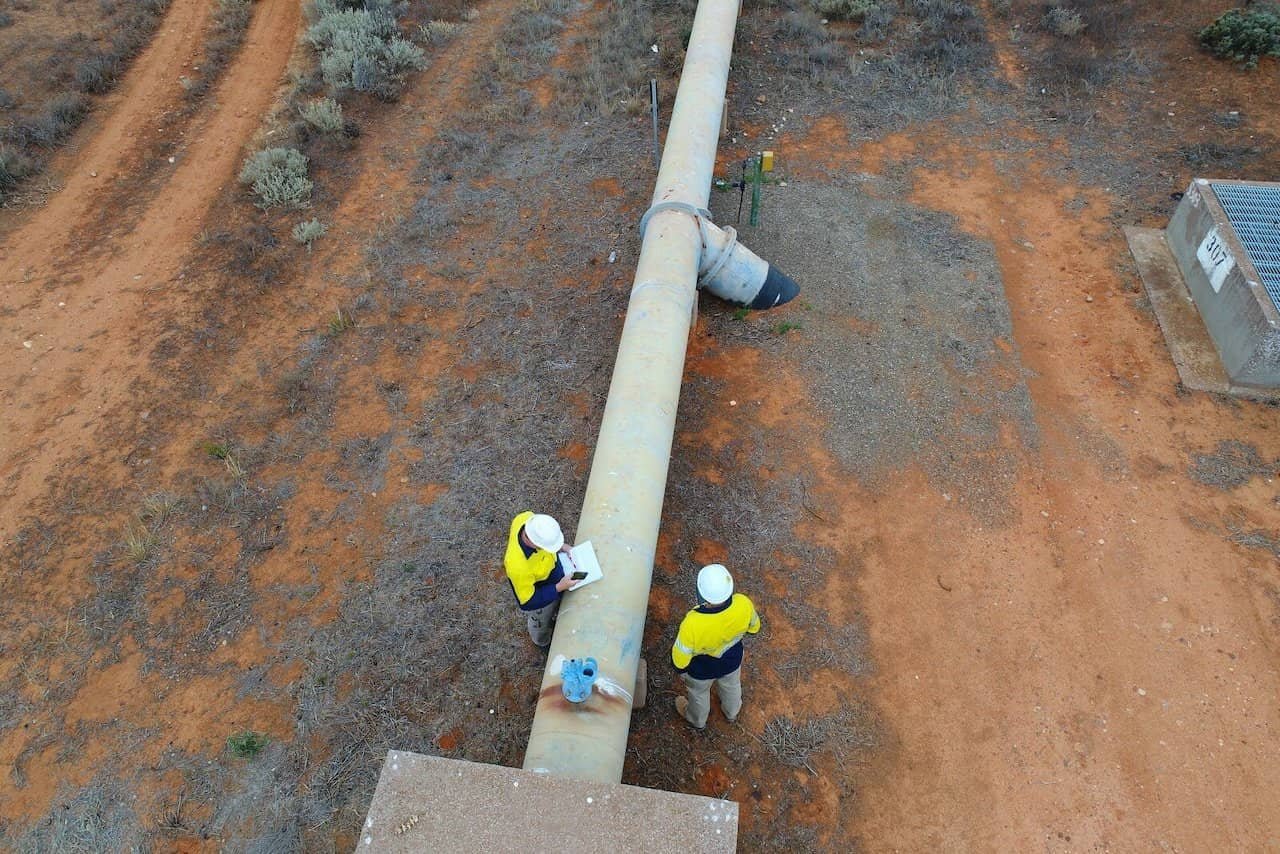

Every pipeline presents unique challenges. When you engage our pigging services, we bring and operate all required equipment—pig launchers, receivers, pigs tailored for your line, and advanced tracking systems. Our technicians handle setup, operation, and data analysis, ensuring you don’t have to worry about system components or technology.

Pigging systems can be fully automated or manual, depending on pipeline size, frequency, and industry application.

The Pipeline Pigging Process

The pigging process involves several steps to ensure proper cleaning and inspection of the pipeline.

First, the pipeline must be prepared for pigging. To prevent damage to the pig and promote its movement, the pipeline must be isolated with all appropriate valves shut or opened accordingly. Next, the pig is inserted into the pipeline using a launching station. Once installed, the pig is propelled forward by the flow of material in the pipeline or by an external energy source. During this process the pig cleans or inspects the interior of the pipeline. Special sensors and monitoring equipment track the pig’s movement. A receiving station, located at the end of the pipeline, collects the pig and any debris removed from the pipeline.

After the pig has been removed, the pipeline must be inspected to ensure it has been properly cleaned or inspected. This is accomplished by visual inspection, ultrasonic testing, or other techniques. If any issues are detected during this post-pigging inspection, further maintenance or repairs may be required before the pipeline can be put back into service.

The pigging process is designed to properly clean or inspect pipelines in order to reduce the risk of downtime, prevent leaks and spills, and extend the life of the pipeline. By following a rigorous

pigging process, pipeline operators can ensure their pipelines are operating at peak efficiency and meeting regulatory requirements.

The pigging process involves the following steps:

Step 1: Preparation

The pipeline is isolated and set up for pigging. Valves are adjusted, and launch/receive equipment is secured.

Step 2: Launching the Pig

A pig is inserted into the launcher and pushed through the pipe using fluid pressure, compressed air, or gas.

Step 3: Cleaning or Inspecting

The pig performs its task as it travels, scraping residue, separating products, or scanning pipe walls.

Step 4: Monitoring the Pig

Its location is tracked to ensure it completes the run. If it encounters issues, tracking equipment helps pinpoint its position.

Step 5: Receiving the Pig

It exists at the receiving station where the debris or data it is collected.

Step 6: Post-Run Analysis

The pipeline is inspected visually or digitally to assess cleaning effectiveness or evaluate inspection data.

This method allows pipelines to remain operational (in some cases) or be quickly returned to service after cleaning or inspection.

Industries That Use Pipeline Pigging

Pigging is not limited to oil and gas. It’s used in diverse industries:

Oil & Gas: For pipeline integrity, separation, and flow assurance.

Food and Beverage: Chocolate, dairy, sauces, beer, and juices

Personal Care: Shampoo, toothpaste, cosmetics

Household Products: Detergents, cleaning liquids

Chemical Manufacturing: Paints, resins, coatings

Pharmaceuticals: Liquid medications and sterile compounds

These industries rely on pigging to reclaim valuable products, prevent contamination, and minimize downtime between batch changes.

We serve a broad range of industries with our pigging services, customizing solutions for oil & gas, food and beverage, chemical manufacturing, pharmaceuticals, and more.

Challenges and Limitations of Pipeline Pigging

While pipeline pigging is an effective maintenance method, several challenges and limitations are associated with the process.

Pipeline design can impact the effectiveness of pigging. For example, pipelines with sharp bends or changes in diameter may require special pigs to navigate these obstacles. A limited array of pigs may be available for use in smaller-diameter pipelines. When planning to use the pigging process, operators must carefully consider the design of their pipelines. Pipelines not well suited for pigging may require modifications or the use of special equipment.

Operators must also consider the frequency of pigging. If done too infrequently, debris and contaminants can build up inside the pipeline, making cleaning more difficult. Conversely, if pigging is performed too frequently, the pipeline may be at risk for unnecessary wear and tear thereby increasing the risk of damage. To best address these challenges, operators should develop a pigging schedule adapted to the specific needs of their pipeline. The material being transported, the age of the pipeline, and the environmental conditions under which the pipeline operates, must all be considered when creating this schedule.

Challenges and limitations of pipeline pigging can be addressed through careful planning, design, and equipment selection. By working closely with experienced pigging professionals and following best practices, pipeline operators can ensure their operations are effective, efficient, and safe.

Pipeline Experts: Inspection, Cleaning, Coating & More

Certified solutions for inspection, pre-commissioning, cleaning, internal coating, ice pigging™, mapping, and turnkey pipeline projects—maximizing safety and reliability at every stage.

Conclusion

Pipeline pigging is crucial to maintaining efficient and safe pipeline operations. Regular pigging removes debris and contaminants, prevents corrosion, and detects potential issues before they become major problems. These actions help reduce the need for costly shutdowns and repairs, increase the lifespan of the pipeline, and minimize negative environmental impact.

To implement a successful pigging program, pipeline operators should work closely with experienced professionals who can provide guidance on pig selection, pigging frequency, and other best practices. Well developed pigging programs help operators ensure their pipelines are working at peak performance and are complying with regulatory requirements.

FAQs: Pipeline Pigging

What is pipeline pigging in simple terms?

Pipeline pigging is the process of sending a device called a “pig” through a pipeline to clean, separate products, or inspect the internal condition of the pipe. The pig is pushed by product flow or a driving medium (like gas, air, or water) and performs its job as it travels, then is collected at the end of the line.

What are the main types of pipeline pigs?

Common pigs include cleaning pigs, inspection pigs (smart pigs), batching pigs, gauging pigs, and product recovery pigs. Cleaning pigs scrape and push debris, smart pigs measure wall condition, batching pigs separate products, gauging pigs check for deformation or bore issues, and product recovery pigs reclaim residual product in sanitary or high-value systems.

How does a pig actually move through a pipeline?

A pig is inserted into a launcher, then driven through the pipeline by pressure from the product in the line or from a separate source such as compressed air, nitrogen, or water. As it travels, it maintains contact with the pipe wall via cups, discs, or foam, which also help it push debris forward or carry sensors for inspection.

Why is pipeline pigging important for maintenance and integrity?

Pigging removes debris, scale, and contaminants that restrict flow and contribute to corrosion. It also lets operators inspect wall condition and detect defects early. Together, that means fewer unplanned shutdowns, fewer leaks or spills, extended pipeline life, and better compliance with internal standards and regulatory requirements.

Can pigging be done while the pipeline is still in service?

In some cases, pigging can be performed while the line is operating, especially for cleaning or batching. In other situations—such as certain inspections, hydrotests, or when valves and connections must be adjusted—sections of the system may need to be isolated. The approach depends on pipeline design, operating conditions, and safety requirements.

How often should a pipeline be pigged?

There’s no single schedule that fits every system. Pigging frequency depends on factors like product type, pipeline age, internal coating condition, operating pressure and temperature, and how much debris or buildup the system tends to generate. Many operators use a preventative schedule based on performance trends and inspection data instead of waiting for a problem.

Which industries use pipeline pigging besides oil and gas?

Beyond oil and gas, pigging is widely used in food and beverage, personal care, household products, chemicals, and pharmaceuticals. In these sectors, pigs help recover valuable product from the line, prevent cross-contamination between batches, reduce water and cleaning chemical use, and shorten changeover times.

What are some common challenges with pipeline pigging?

Challenges include complex pipeline geometry (tight bends, diameter changes, tees), older lines with limited pigging provisions, choosing the right pig for the job, and setting a smart pigging frequency. Poor planning can lead to stuck pigs, incomplete cleaning, or unnecessary wear. That’s why pigging design, tracking, and post-run analysis are so important.

Can pigging damage a pipeline or its internal coating?

If the wrong pig or operating conditions are used, there’s a risk of damaging internal coatings or stressing pipeline components. Best practice is to match pig design and operating pressures to the pipe material, coating condition, and debris profile. Experienced pigging teams will adjust tools and procedures to protect the asset while achieving the cleaning or inspection goal.

Why partner with a specialist like American Pipeline Solutions for pigging?

Effective pigging requires more than just the right tool. APS designs the full program—pig selection, launch and receive procedures, tracking, safety controls, and post-run analysis. Our team brings the required equipment, certifications, and documentation to support inspection, maintenance, and regulatory needs, so your pipelines stay clean, reliable, and ready for service.

At American Pipeline Solutions, we provide end-to-end pigging services—from cleaning and inspection to internal coating, 3D mapping, and turnkey project execution.

Looking to reduce downtime, boost throughput, or improve pipeline integrity?

Contact us today to discuss how a custom pigging solution can support your operations.

Ice Pigging™ vs Water Flushing (A Comparison)

Information provided in this blog reviews the difference between Ice Pigging™ and water flushing.

All drinking water pipes, in all water distribution pipes around the world will, over time, require cleaning due to the potential build-up of sediment, biofilm, iron, manganese, and trihalomethanes (THMs). Although many forms of sediment may not initially cause any harm to the quality of the water or the end user (the general public), added to the fact that disinfection treatment can help to kill off any bad bacteria, nevertheless over time, biofilms are likely to grow exponentially, forming a slimy substance within the pipe. In turn, THMs (which are a byproduct of the use of chlorine in potable water systems) may become an issue. Depending on the source of the water supply, manganese or iron may be very prevalent in the water, causing discolored water issues and complaints.

Pipeline Experts: Inspection, Cleaning, Coating & More

Certified solutions for inspection, pre-commissioning, cleaning, internal coating, ice pigging™, mapping, and turnkey pipeline projects—maximizing safety and reliability at every stage.

For most water companies and municipalities, the preferred solution to resolve these issues, is water flushing.

Water flushing is a term used in the water sector whereby a water operator or technician will go from hydrant to hydrant, systematically opening the valves one at a time, allowing the water to discharge, usually to waste down a nearby stormwater drain. The operator will do this for a certain amount of time, usually based on the flow rate, to allow a pre-determined amount of water to be discharged in the hope that the velocity of the rushing water will be high enough to pick up any loose sediment that has built up in the line.

This is where the problem lies because the simple fact is that water alone provides a relatively low shear on the inside of the pipe wall. In other words, the scouring power is very poor, and therefore, the water must be allowed to travel at high velocity to increase the shear on the pipe wall. Quite often, though, these velocities are not achievable due to several factors, including limited system pressures, tuberculation or scale build-up restricting the flow, or simply insufficient volumes.

A technique called Uni-Directional Flushing (UDF) is an enhanced means of water flushing, often thought to be more effective than “standard” flushing. These UDF programs are designed to maximize the potential velocities and, thereby, remove greater amounts of sediment from the mains. However, the fact remains that water provides low shear (or scouring power), and so even the best thought-out UDF plan is often insufficient to remove all the sediment from the system.

Even when the velocity in a main is at an acceptable level, there is then the (very serious) factor of water wastage. It is generally thought by water consultants around the world that at least 4-5 times the volume of the pipe being cleaned needs to be flushed out of the line before the water flushing is at all effective. To put that number into perspective, that represents almost 69,000 gallons of water in just one mile of 8-inch water main (about 10 blocks), or 108,000 gallons (enough to fill 5-6 average-sized in-ground swimming pools) in a mile of 10-inch water main. Many smaller communities or municipalities don’t even have the luxury of large storage reservoirs sufficient to provide the required amount of water, and in many states in the US, severe droughts have led to heavy restrictions on the waste of precious water. In any case, ask yourself, “why would you pay to collect, store, and treat water just to flush it away before it gets to the end customer?”.

This is where a (relatively) new, advanced pipe-cleaning technique called Ice Pigging™ comes to the fore.

Ice Pigging™ uses a slush ice (or ice slurry) injected into the main, where it then flows through the line using normal system flows and pressures and is discharged out at a pre-determined point. As it flows through the main, the ice crystals pick up the sediment by scouring the pipe walls, carrying it in the body of the ice and out of the line at the discharge point, where it can be safely disposed.

Simply by turning water into ice crystals, you can achieve up to 1,000 times more shear (scour power) on the inside of the pipe wall than flushing plain water. The ice even has the ability to do this at much slower velocities than water, so for those situations where the desired velocity is not achievable, Ice Pigging™ will obtain a far superior clean.

Although it is inevitable that some water may be wasted during an Ice Pigging™ operation, it will be up to 70% less wastage than a similar flushing project, and yet the cleaning efficacy will be so much superior.

Cost?

Although Ice Pigging™ may initially appear to be more costly, a recent study carried out in Australia found that while Ice Pigging™ is more expensive on a ‘$ per foot’ basis, when using the indicator of ‘$ per lb. of sediment removed’, Ice Pigging™ is approximately 6 times cheaper. The study also found that Ice Pigging™ removed up to 17 times more sediment from the mains compared to flushing while using half the amount of water.

It is hypothesized that the superior clean achieved by Ice Pigging™ will result in less discolored water complaints and therefore lead to cost savings in the reduction of unscheduled flushing programs and the frequency of mains cleaning of water supply zones (P. Dang et al., 2014).

Another finding from the study indicated that Ice Pigging™, a water supply zone improves the penetration of chlorine residuals.

(Note: Due to the success of this study, the water company involved commenced a full-scale program to Ice Pig approximately 250 miles of water mains each year for the following five years).

Pipeline Experts: Inspection, Cleaning, Coating & More

Certified solutions for inspection, pre-commissioning, cleaning, internal coating, ice pigging™, mapping, and turnkey pipeline projects—maximizing safety and reliability at every stage.

Benefits of Ice Pigging™ over Flushing

Lower velocities required

Smaller volumes required

Superior clean

Drought Friendly (Less waste)

Shorter downtimes

Cheaper when using the indicator of $ per lb. of sediment removed

Case Study

In 2022, a comparison test was carried out at an Ice Pigging™ project for a large Idaho city. This included certain ‘problem’ areas that were flushed by means of a UDF program followed the very next day by Ice Pigging™ with the aim of determining how much additional sediment was able to be removed. You can clearly see from the photos below of samples taken at the ice discharge hydrant, how much sediment was actually removed. Note the ‘clear’ sample in each picture is a sample of the discharge before the ice arrives (essentially flushing water), then how the samples darken with the amount of sediment suspended in the ice slurry, a clear indication of the superior cleaning effect of the Ice Pig.

FAQs: Ice Pigging™ vs. Water Flushing

What is Ice Pigging™ in drinking water mains?

Ice Pigging™ is an advanced pipe-cleaning technique that uses a thick slurry of ice injected into a water main. As the ice moves through the pipe under normal system pressure, the ice crystals scour the internal walls, pick up sediment and biofilm, and carry it out to a discharge point where the slurry and debris can be safely removed.

How does Ice Pigging™ differ from standard water flushing?

Standard flushing relies on high-velocity water alone to stir up loose material from hydrant to hydrant, but water has relatively low shear on the pipe wall and often can’t generate enough scouring power. Ice Pigging™ uses ice crystals to create far higher shear at much lower velocities, removing significantly more sediment and deposits than conventional flushing or even uni-directional flushing (UDF).

Why is water flushing often not enough to clean distribution pipes?

Flushing with water alone delivers limited scouring force on the pipe wall, even when operators try to push velocity higher. System pressure limits, build-up inside the main, and available water volumes all reduce effectiveness. As a result, biofilm, iron, manganese, and other deposits can remain in the system, continuing to cause discolored water complaints and quality concerns.

How much more effective is Ice Pigging™ than flushing?

Turning water into ice crystals dramatically increases shear at the pipe wall—up to 1,000 times higher than plain water. In comparative work, Ice Pigging™ removed substantially more sediment from mains than flushing alone, even when UDF had already been performed. In one study, Ice Pigging™ removed up to 17 times more sediment while using roughly half the water.

Does Ice Pigging™ reduce water wastage compared to flushing?

Yes. Traditional flushing typically requires four to five times the pipe volume to be discharged before results are acceptable, which can translate to tens of thousands of gallons per mile of main. Ice Pigging™ can cut that wasted volume by up to 70% while still delivering a far superior clean, making it more sustainable and better suited to drought-affected or supply-limited systems.

Is Ice Pigging™ more expensive than flushing?

On a simple “dollars per foot” comparison, Ice Pigging™ can appear more expensive than standard flushing. However, when you measure cost per pound of sediment actually removed, Ice Pigging™ becomes much more economical. A study cited in the article found Ice Pigging™ to be around six times cheaper on a cost-per-pound-of-sediment basis, because it removes far more material with less wasted water.

What types of deposits can Ice Pigging™ remove from water mains?

Ice Pigging™ is designed to remove a wide range of deposits that form in potable water systems over time, including sediment, biofilm, iron, manganese, and fat, oil, and grease (FOG). By scouring the pipe walls and suspending this material in the ice slurry, the process helps reduce discolored water complaints and improve overall water quality.

How does Ice Pigging™ impact chlorine residuals and water quality?

By stripping away biofilm and sediment, Ice Pigging™ improves internal pipe cleanliness, which can help chlorine residuals penetrate further into the network. Cleaner pipes and more stable residuals support better water quality, fewer complaints, and reduced need for unscheduled flushing in problem zones.

Is Ice Pigging™ suitable for systems with limited storage or drought conditions?

Yes. Because Ice Pigging™ uses much smaller water volumes than conventional flushing to achieve a better clean, it is well suited to smaller communities, utilities with constrained storage, and regions under drought-related restrictions. The technique reduces waste while still addressing discolored water and sediment issues in distribution mains.

Can Ice Pigging™ be used after a UDF program has already been run?

It can, and that’s often where the benefits are most visible. In the Idaho case study described, a problem area was flushed using UDF one day and Ice Pigged the next. Samples taken at the discharge hydrant clearly showed how much additional sediment the ice slurry removed, even after the system had already undergone a traditional flushing program.

Unlocking the Benefits of Smart Pigging - The Future of Pipeline Maintenance

Information provided in this blog provides an overview of smart pigging: its technology, applications, and advantages, as well as its limitations.

Introduction

A. Definition of Smart Pigging:

In-line inspection, commonly referred to as “smart pigging,” uses specialized tools known as “smart pigs” to inspect pipelines. The smart pigs move through the pipelines collecting data relevant to their interior condition. This non-invasive process helps ensure the reliability and safety of pipelines. The process also offers an innovative solution to the task of pipeline maintenance.

B. Purpose of the Blog:

Information provided in this blog provides an overview of smart pigging: its technology, applications, and advantages, as well as its limitations.

C. Importance of Pipeline Maintenance:

As critical components of numerous industries ( i.e. oil and gas, water and wastewater, and chemical) pipelines must be properly maintained to ensure longevity, reliability, and safety. Failure to do so risks corrosive damage leading to leaks, spills, and other dangers. By proactively addressing issues thereby preventing costly problems, smart pigging affords users a practical, efficient solution for pipeline maintenance.

Pipeline Experts: Inspection, Cleaning, Coating & More

Certified solutions for inspection, pre-commissioning, cleaning, internal coating, ice pigging™, mapping, and turnkey pipeline projects—maximizing safety and reliability at every stage.

What is Smart Pigging?

A. Technology Overview

Smart pigging technology uses specialized tools to inspect pipeline interiors. These tools are called “pigs.” Equipped with various sensors, pigs detect and measure pipeline conditions such as corrosion, wear, geometry, and wall thickness. The data collected by the pigs is stored and retrieved at the end of the pipeline run. Analysis of the data determines the condition of the pipeline and identifies any potential problems.

B. Types of Pigs

Several different kinds of pigs are used in smart pigging. Each type is designed to serve a specific inspection need. The most common types include magnetic flux leakage pigs, ultrasonic pigs, and caliper pigs.

C. How It Works

The smart pigging process starts by inserting the tool into the pipeline. The flow of the product being transported through the pipeline propels the pig. As it moves through the pipeline, the pig collects data and transmits it to the surface. Once it reaches the end of the pipeline, the pig is removed. The data collected by the pig is analyzed to determine next steps for the proper maintenance of the pipeline.

Advantages of Smart Pigging

A. Cost-Effective

The primary advantage of smart pigging is cost-effectiveness. Because they often require shutting down the pipeline, traditional methods of inspection can be time-consuming and costly. Smart pigging not only can be conducted without interruption of service, but also produces more accurate and detailed data reducing the need for additional follow-up and repairs.

B. Time-Efficient:

Additionally, smart pigging is time efficient. Pigs travel rapidly and without interruption providing quick and accurate assessments of the pipeline’s interior conditions. The company can then make better informed decisions regarding maintenance and repairs leading to less downtime and increased productivity.

C. Increased Safety

Smart pigging inspects pipelines from the inside minimizing the risks of accidents and spills associated with more invasive, traditional techniques. This safer alternative also helps companies identify and address potential hazards more quickly before they become serious problems.

D. Improved Data Collection

The comprehensive data collection provided by smart pigging allows companies to monitor pipeline conditions over time. Information about wall thickness, corrosion, wear, and pipeline geometry enables companies to address maintenance needs in a timely fashion thereby preventing more costly problems.

Applications of Smart Pigging

A. Detection of Corrosion and Wear

Smart pigging is often used to detect corrosion and wear in pipelines. Pigs equipped with magnetic flux leakage or ultrasonic sensors can detect changes in the pipeline’s magnetic field or ultrasonic wave patterns. Such changes can indicate corrosion or other weaknesses in the pipe wall. The pigs’ sensors transmit this data to the surface for further analysis. The results help determine the extent of any damage and next steps for maintenance.

B. Inspection of Pipeline Geometry

For best performance, pipelines must be assessed for any deviations from their original geometry. Using caliper sensors, smart pigs can measure the diameter of the pipeline and detect any deformities and/or distortions. Left unaddressed these deviations can cause increased friction and stress leading to leaks or ruptures.

C. Evaluation of Pipeline Cleanliness

Cleanliness is important for efficiency and safety of pipelines. Smart pigs such as American Pipeline Solutions’ Smart Foam Tool are equipped with sensors to detect debris or build-up impeding the flow of the fluid or gas transported by the pipeline. Evaluating the cleanliness of the pipeline helps protect it from blockages or reduced flow rates.

D. Measurement of Pipeline Wall Thickness

Smart pigs equipped with ultrasonic sensors can measure a pipeline’s wall thickness. This information is critical in determining the structural integrity of the pipeline. Data indicating wear corrosion or compromised wall thickness helps companies more accurately establish the maximum allowable operating pressure (MAOP).

Limitations of Smart Pigging

A. Limitations of Different Types of Pigs

Of course, as with any tool, smart pigging has limitations. For example, some smart tools may be unable to detect corrosion in pipelines made of non-ferromagnetic material. Ultrasonic pigs may have limited ability to identify corrosion in pipelines with thick coatings or heavy scale buildup. Recognizing these limitations is important when choosing the appropriate smart pigging solution for pipeline maintenance.

B. Limitations of Pipeline Configuration

Pipeline configuration also impacts the effectiveness of smart pigging. Pigs may have difficulty navigating pipelines with tight bends or numerous changes in direction. Pipelines with multiple branches or complex configurations may require more than one pig or special equipment to perform the inspection. Most smart pigs require a launcher and receiver to be deployed and recovered.

C. Limitations of Operating Conditions

Operating conditions are another factor affecting the accuracy and reliability of the data collected by this smart tool. High pressure or temperature can interfere with the sensors on the smart pig. Fluid flow and viscosity can impede its movement. Choosing a smart pigging solution requires careful consideration of the pipelines’ operating conditions.

Pipeline Experts: Inspection, Cleaning, Coating & More

Certified solutions for inspection, pre-commissioning, cleaning, internal coating, ice pigging™, mapping, and turnkey pipeline projects—maximizing safety and reliability at every stage.

Smart Pigging in Pipeline Inspection and Diagnostics

Smart pigging plays a critical role in modern pipeline integrity management. It enables operators to inspect pipelines from the inside, without interrupting flow, and provides data that informs both immediate decisions and long-term asset planning. In new pipeline installations, smart pigging establishes a performance baseline, while in older systems, it helps track aging and wear over time.

One of the key advantages is its ability to perform pipeline condition assessments through trend comparisons of successive inspection runs. These comparisons make it possible to detect gradual deterioration, such as increasing corrosion or wall thinning, and address it before it escalates into a major issue.

Smart pigging is also used for pressure pipe inspection, helping operators confirm the Maximum Allowable Operating Pressure (MAOP). By providing accurate internal measurements and identifying anomalies, smart pig data supports regulatory compliance and safe operations.

Another major application is in corrosion monitoring. Smart pigs can detect and track corrosion rates over time, giving operators the ability to assess how quickly corrosion is progressing in different sections of the pipeline.

All this data feeds directly into risk-based maintenance planning. Rather than relying on fixed maintenance schedules, operators can make informed decisions based on quantifiable defect data—prioritizing resources where they are most needed and extending the service life of infrastructure safely.

Industries That Use Smart Pigging

Smart pigging is not limited to a single industry. Its benefits are recognized across a wide range of sectors that depend on pipeline infrastructure for critical operations.

In the oil and gas industry, smart pigging is widely used in both crude and natural gas transmission pipelines. It helps detect early-stage corrosion, metal loss, and geometric deformities that could compromise flow or lead to leaks.

Water utilities employ smart pigs for the inspection of both potable water and wastewater pipelines. These tools allow for non-invasive diagnostics that identify sediment build-up, blockages, and structural issues—all while keeping the water supply operational.

In the chemical processing sector, pipelines often carry corrosive substances under pressure. Smart pigging is essential for monitoring internal conditions, ensuring product purity, and detecting potential leakage points that could lead to safety hazards or environmental violations.

The energy and power industries, especially those involving high-pressure steam or hydrogen delivery, use smart pigs to validate the integrity of their pipelines under extreme conditions. This prevents system failure and ensures continuity in power generation.

Lastly, industrial manufacturing facilities depend on pipeline systems within their plants for efficient operations. Smart pigging helps verify pipeline health, clean internal surfaces, and maintain system reliability across various processes and production lines.

Conclusion

Future of Smart Pigging

Smart pigging is a rapidly evolving technology with a bright future. The demand for efficient, cost-effective pipeline maintenance continues to grow. Smart pigging offers an innovative and reliable solution. Advancements in sensors and data analysis will lead to even greater accuracy, efficiency, and safety of this technology.

Importance of Pipeline Maintenance

Pipeline maintenance is essential to the safe and efficient operation of pipelines. Smart pigging is a powerful tool for achieving this goal. By providing accurate analyses of pipeline conditions, smart pigging enables companies to proactively address issues before they become serious problems.

Final Thoughts

Smart pigging is a powerful and innovative technology changing the way companies approach pipeline maintenance. By providing a more accurate view of pipeline conditions, this smart tool reduces costs, improves efficiency, and increases safety. Clearly, the future is bright for smart pigging as an indispensable component of pipeline maintenance.

Frequently Asked Questions

How often should pipelines be smart pigged?

Run intervals depend on fluid type, operating conditions, and regulations. Annual to biennial runs are common for critical systems; less frequent use is possible for lower-risk lines.

Is smart pigging necessary for all pipelines?

Pipelines transporting hazardous fluids or under high pressure greatly benefit from smart pigging. Newer or low-risk systems may require less frequent inline inspection.

What is the difference between smart pigging and pipe inspection?

Smart pigging is a form of pipe inspection, specifically in-line inspection using specialized tools. It covers more than geometry; smart pigs also collect pressure-related, metal-loss, and corrosion data.

Pipeline Effects on Environment: Enhancing Sustainability

Learn about pipeline effects on the environment and how American Pipeline Solutions is enhancing sustainability through eco-friendly pigging.

Pipeline effects on the environment are a serious concern for many governments, businesses, and homeowners. Yet many still don't realize the significant negative effects the construction and placement of pipelines can have on surrounding environments, ecosystems, and habitats.

Pipeline contractors and operators are tasked with finding solutions that allow them to lessen the harm done to environments while meeting environmental codes and regulations. It's challenging for companies to continue running efficient and cost-effective pipelines while considering environmental impacts.

Luckily, there are several ways that companies can offset or avoid the environmental impact of pipeline construction and placement. Our team at American Pipeline Solutions discusses how pipelines affect the environment. We also talk about how the harmful effects of pipeline construction and procedures can be reduced, as well as the environmental benefits of pipeline pigging.

After all, pipeline pigging is one of the best innovations to clean pipelines and mitigate environmental harm once they have been placed.

Pipeline Experts: Inspection, Cleaning, Coating & More

Certified solutions for inspection, pre-commissioning, cleaning, internal coating, ice pigging™, mapping, and turnkey pipeline projects—maximizing safety and reliability at every stage.

How Does the Construction and Placement of a Pipeline Affect the Environment?

There are numerous ways that the construction and placement of a pipeline affect the environment. Below we have broken down a few ways pipelines negatively affect our environment.

Products Carried Through Pipelines Cause Damage When Released

It is believed that when the products are transported through pipelines like sewerage, water, oil, and gas, the environment can be impacted, property damages can occur, and injuries or fatalities can arise.

How hazardous a pipeline leak or rupture is to the environment can depend on many factors, including the pipeline's size, the product it carries, the population and natural resources near the pipeline, and the operating pressure. Look below to see how certain products or materials harm the environment when there is a leak or rupture in the pipeline.

1. Habitat Loss and Fragmentation

One of the most immediate consequences of pipeline construction is habitat destruction. Clearing large stretches of land disrupts ecosystems and fragments habitats, making it harder for wildlife to migrate, reproduce, or access food and water. In sensitive areas, this can lead to population declines or even endangerment of certain species.

2. Erosion and Water Quality Degradation

Excavation and construction activities disturb soil and vegetation, increasing the risk of erosion. Sediment runoff can enter nearby streams, rivers, and wetlands, reducing water clarity and carrying pollutants that harm aquatic ecosystems. This sedimentation can also smother fish eggs, destroy spawning grounds, and disrupt the food chain.

3. Air Pollution

Compressor stations and maintenance operations along pipelines can emit methane and other volatile organic compounds (VOCs). These emissions not only degrade local air quality but also contribute to the formation of ground-level ozone, which is harmful to both humans and wildlife.

4. Greenhouse Gas Emissions

Methane, the primary component of natural gas, is over 25 times more potent than carbon dioxide in trapping heat over 100 years. Even small leaks from pipelines contribute to global greenhouse gas emissions, intensifying climate change. While carbon dioxide from combustion is widely known, methane emissions from pipeline leaks are often overlooked yet highly significant.

5. Spills and Leaks

It is believed that when the products are transported through pipelines like sewerage, water, oil, and gas, the environment can be impacted, property damages can occur, and injuries or fatalities can arise.

How hazardous a pipeline leak or rupture is to the environment can depend on many factors, including the pipeline's size, the product it carries, the population and natural resources near the pipeline, and the operating pressure. Look below to see how certain products or materials harm the environment when there is a leak or rupture in the pipeline.

Between the two, a pipeline leak is far more common than a pipeline rupture because a leak is a slow release of a product, while a rupture is a sudden occurrence. Pipeline leaks also cause less damage than pipeline ruptures.

According to experts, pipeline incidents have numerous causes. The most common causes are material welding and equipment failure, corrosion, excavation damage, and natural force damage.

How Can the Harmful Impact of the Construction and Placement of a Pipeline Be Reduced?

Fortunately, there are numerous ways that the harmful impact of construction and placement of pipelines can be reduced. We have briefly listed these ways below.

Offset habitat loss: It's true that, at times, habitat loss, emissions, and other negative environmental impacts are unavoidable when constructing and placing a pipeline. Yet, in these instances, a company or organization can prioritize offsetting the damages to the environment. For example, companies and governments can create replanting tree initiatives or donate to local nature reserves.

Better planning of pipeline routes: One of the best ways to reduce the harmful impact of pipeline construction and its impact on the environment is to insist on better planning of pipeline routes. If a pipeline route is planned properly, many environmental problems can be avoided. For example, a company will avoid laying pipes over vital ecosystems if a pipeline route is planned correctly.

Remember, even if the pipeline structure isn't the problem, the heavy equipment and excavation involved will likely cause environmental damage. So, try to avoid environmental areas of deep concern and instead plan a pipeline route along previously disturbed areas while also using already established roads to avoid unnecessary construction damages.

Maintain pipelines: It's crucial that once pipelines have been constructed and placed that they are maintained to ensure further harm is not caused to the surrounding environment. If pipelines are not maintained with innovative solutions like pipeline pigging, leaks, build-up, and other pipeline problems could destroy vegetation, harm wildlife, and compound air and water pollution problems. Alongside pigging solutions offered by American Pipeline Solutions, operators should also perform routine maintenance checks and services.

Eco-friendly coatings and corrosion protection:

Using environmentally friendly pipeline coatings is a proactive way to reduce long-term environmental risk. These coatings help protect pipeline surfaces from rust, corrosion, and chemical degradation — all of which can lead to leaks. By choosing low-VOC (volatile organic compound) or biodegradable coatings, operators can enhance sustainability without compromising durability.

Emergency response plans:

No matter how careful the planning and construction, spills and leaks can still occur. That’s why having a well-defined emergency response plan is essential. These plans should include rapid containment strategies, training for local personnel, and coordination with environmental agencies to minimize the damage caused by pipeline incidents.

Technological advancements:

Drones, AI, and satellite-based monitoring systems are revolutionizing pipeline oversight. These technologies allow for real-time inspections, early leak detection, and faster issue resolution — all while minimizing the need for disruptive ground-based inspections. Leveraging such tools ensures pipelines are monitored more frequently and with greater accuracy.

Horizontal directional drilling (HDD):

HDD is a trenchless method that enables pipelines to be installed beneath rivers, wetlands, and other environmentally sensitive areas. By avoiding surface excavation, HDD dramatically reduces soil disturbance, erosion, and damage to natural habitats. It’s one of the most environmentally conscious construction techniques available today.

What Are the Environmental Benefits of Pigging?

As we mentioned above, pipeline pigging is crucial to pipeline maintenance. Without routine pipeline pigging, many problems could arise. Fortunately, pigging has many environmental benefits depending on the specific pigging method chosen for a pipeline.

For example, the ice pigging environmental impact is low. This is one of the most environmentally-friendly pipeline cleaning solutions because it uses up to 50% less water than other cleaning options.

Additionally, ice pigging pipelines don't need to be excavated or dug up if a pig gets stuck because it will simply melt. Other pigging solutions also offer enhanced efficiency without utilizing harmful cleaning agents.

With pigging (depending on the type), there won't be the risk of corrosion or accidental hazardous chemical leakage into oceans, rivers, lakes, and surrounding environments. Moreover, with pigging, there is less waste which means fewer carbon monoxide emissions and more product recovery.

Pipeline Experts: Inspection, Cleaning, Coating & More

Certified solutions for inspection, pre-commissioning, cleaning, internal coating, ice pigging™, mapping, and turnkey pipeline projects—maximizing safety and reliability at every stage.

Common Environmental Regulations for Pipelines

Pipeline construction and operation in the U.S. is governed by a range of environmental regulations designed to minimize harm to ecosystems and public health. The Environmental Protection Agency (EPA) sets federal standards that cover everything from water discharge permits to spill response planning.

Operators must also comply with the Clean Water Act, Clean Air Act, and National Environmental Policy Act (NEPA), which requires thorough environmental impact assessments before new pipelines are approved. On the state level, additional permitting and monitoring requirements may apply, depending on the pipeline’s location and the sensitivity of the surrounding environment.

Long-Term Environmental Risks of Aging Pipelines

As pipelines age, their risk of failure increases. Older infrastructure is more susceptible to corrosion, material fatigue, and joint failure, all of which can lead to chronic leaks or sudden ruptures. These incidents don’t just pose immediate safety risks — they often result in long-term environmental degradation. Leaked oil or gas can seep into soil, contaminate groundwater, and kill off plant and animal life over time.

In addition, many older pipelines were installed before modern environmental regulations were in place, meaning they may lack adequate protections or monitoring systems. Regular inspection and phased replacement are essential to mitigating these long-term risks.

How Pipeline Monitoring Technology Enhances Sustainability

Modern technology plays a key role in making pipeline systems more sustainable and environmentally responsible. Smart pigging devices — specially designed tools that travel through the pipeline — can detect internal corrosion, cracks, and deformations before they become major problems. IoT (Internet of Things) sensors installed along the pipeline provide real-time data on pressure, temperature, and flow rates, alerting operators to anomalies that could signal a leak.

In some systems, AI-driven analytics are used to predict potential failure points based on historical and live data, enabling preventative maintenance and reducing the risk of environmental incidents. These technologies not only protect ecosystems but also help pipeline operators stay compliant and efficient.

Speak With an APS Representative Today To Find the Best Pipeline Pigging Solution for You

It's evident that pipeline construction and placement have numerous harmful impacts on the environment. Yet, fortunately, there are ways to enhance sustainability and mitigate some of the harm environments face, like replanting trees and maintaining pipelines with pigging solutions.

Should you want to learn more about the pipeline pigging methods available for different types of pipelines, you can speak with us at American Pipeline Solutions. We offer various pipeline pigging solutions to suit the needs of varying projects.

FAQs:

How do pipelines affect the environment during construction?

Pipeline construction disturbs land, vegetation, and wildlife habitats. Activities such as trenching, excavation, and heavy-equipment movement can lead to soil erosion, habitat fragmentation, and water pollution from sediment runoff. APS emphasizes sustainable planning—using existing rights-of-way and directional drilling—to minimize surface disruption and protect sensitive ecosystems.

What are the main environmental risks of pipeline leaks or ruptures?

Leaks and ruptures release the transported product—oil, gas, water, or chemicals—into surrounding soil and waterways. This can contaminate groundwater, harm wildlife, and release greenhouse gases. APS helps operators prevent incidents through regular maintenance, integrity assessments, and pipeline pigging programs that keep systems clean and corrosion-free.

How can pipeline companies reduce environmental impact?

Companies can reduce impact by planning routes that avoid sensitive habitats, applying eco-friendly coatings, maintaining lines with inspection and integrity support, and using technologies like drones, AI monitoring, and leak-detection sensors. APS integrates these practices to help clients stay compliant with EPA and state environmental regulations.

What are the environmental benefits of pipeline pigging?

Pipeline pigging improves environmental performance by preventing leaks, corrosion, and product loss. Modern techniques—such as Ice Pigging™—use up to 50% less water and eliminate chemical cleaning agents. APS’s pigging services minimize waste, reduce emissions, and support sustainability goals for operators across oil, gas, and water systems.

How does Ice Pigging™ support sustainability?

Ice Pigging™ uses a slurry of ice and water to clean pipelines non-abrasively. The ice conforms to internal pipe geometry, removes buildup, and then melts—leaving no solid waste. It’s energy-efficient, water-conserving, and safer for the environment compared with traditional flushing or chemical cleaning methods.

Why is pipeline maintenance essential for environmental protection?

Regular maintenance prevents corrosion, pressure loss, and leaks that can release pollutants. Programs that include inspection, cleaning, and pigging keep pipelines operating within safe parameters. APS helps clients establish maintenance schedules that extend asset life, lower environmental risk, and meet federal compliance requirements.

How do modern technologies improve pipeline sustainability?

Smart pigs, IoT sensors, and AI analytics detect early signs of wear or leaks, allowing proactive repairs. Satellite monitoring and drones reduce the need for disruptive ground inspections. APS combines these innovations with field-proven maintenance to enhance safety, efficiency, and environmental responsibility.

What regulations govern pipeline environmental safety in the U.S.?

Pipeline operations fall under EPA oversight and must comply with the Clean Water Act, Clean Air Act, and National Environmental Policy Act (NEPA). Operators are required to perform environmental impact assessments and maintain spill-response plans. APS aligns its procedures with these federal and state regulations to ensure compliance and sustainability.

What are the long-term environmental risks of aging pipelines?

Aging pipelines face higher risks of corrosion, joint failure, and undetected leaks. These can cause chronic soil and water contamination. APS mitigates such risks through regular inspection and integrity support and replacement planning, helping operators modernize systems before environmental damage occurs.

How does APS help clients enhance pipeline sustainability?

APS delivers service-only solutions—inspection, cleaning, pigging, and maintenance—that reduce emissions, prevent spills, and extend pipeline life. Our approach combines proven field methods with advanced technologies to protect ecosystems while keeping clients compliant and operationally efficient.

Ice Pigging™ Cost Guide for Water & Sewer Mains

What does Ice Pigging™ cost for water and sewer main cleaning? Read this guide from American Pipeline Solutions to find out the associated costs.

Eventually, all water and sewer mains will need to be cleaned as part of a maintenance or rehabilitation program. This is because, with water mains, biofilm develops along the walls of water pipelines, and manganese and iron buildup flake off into portable water that is fed to businesses and homes. Grit and sediment are other problems with water mains.

In sewer mains, flow often becomes restricted because of corners, bends, and depressed sections that collect deposits. When these buildups occur, a reduction in water flow happens, leading to an inadequate water supply.

To clean water and sewer mains, pigging has been a viable solution. Yet, in recent years more municipalities are turning toward Ice Pigging™. This type of pigging is a method that utilizes an ice slurry instead of a solid “pig” to clean pipelines and mains. It is a popular choice because it is known as one of the most cost-effective water and sewer main cleaning solutions.

In our guide, we will tell you the average Ice Pigging™ cost and the factors that influence the cost of this type of pigging procedure. Our team at American Pipeline Solutions also shares why Ice Pigging™ is generally regarded as a cheaper alternative to other pipeline cleaning methods.

Pipeline Experts: Inspection, Cleaning, Coating & More

Certified solutions for inspection, pre-commissioning, cleaning, internal coating, ice pigging™, mapping, and turnkey pipeline projects—maximizing safety and reliability at every stage.

What Is the Average Cost of Ice Pigging™ for Water and Sewer Mains?

It can be challenging to determine the average cost of Ice Pigging™ for water and sewer mains because every project is unique. In most instances, the larger the project, the more expensive it will be. Before we give the average Ice Pigging™ cost, let's discuss the process more in-depth.

Interestingly, Ice Pigging™ was originally designed for portable water mains and later adapted for sewer force mains. This type of pigging procedure has been designed to clean any material pipe, so it's an excellent cleaning solution for municipality water and sewer mains. Yet, not every municipality will be able to afford Ice Pigging™, and this pigging solution isn't suitable for every situation.

For example, ice pigs cannot and should not be used for gravity-fed sewers because ice pigs need the force that pumped water provides to be suitably driven forward along a sewer or water main. Additionally, Ice Pigging™ cannot remove tubercles, hard water deposits, and heavy corrosion, nor can it rehabilitate pipes. Yet Ice Pigging™ can put off rehabilitation costs by removing organic matter, loose materials, and mineral buildup.

So what are the costs of Ice Pigging™ compared to other pigging methods? According to an AWWA webinar, Ice Pigging™ is one of the cheaper water and sewer main cleaning methods. For example, Ice Pigging™ costs an estimated $1.70 to $5.50 per linear foot, while swabbing costs between $5.70 and $9.10 per linear foot, and traditional pigging between $16.10 and $21.00 per linear foot.

As we mentioned previously, the cost of Ice Pigging™ will largely depend on the size of the project. To give a realistic expectation of how much an Ice Pigging™ project could cost a municipality, we want to share a real-world example.

Real-World Ice Pigging™ Municipality Cost Example

In 2014 in Bethlehem, New York, an Ice Pigging™ project clean-up occurred. An Ice Pigging™ procedure cleaned 10,000 linear feet of Bethlehem’s most problematic water mains during this clean-up.

During this project, several neighborhoods with ongoing water problems were attended to. Needless to say, after Ice Pigging™ was completed on the water mains in this area, the waterlines were much clearer.

According to the company involved in this project, Ice Pigging™ costs between $1 and $8 per foot of pipe. So it's unsurprising that a 10,000 linear foot Ice Pigging™ project cost the Bethlehem municipality $30,000. This cost is still less than other traditional pigging methods. If you want to know more about how much an Ice Pigging™ project could cost a municipality, you can talk with us at American Pipeline Solutions.

What Are the Notable Factors That Influence the Cost of Ice Pigging™?

Every Ice Pigging™ project will have a different cost based on different factors. Below are a few reasons why Ice Pigging™ could cost more for a municipality's water or sewer mains cleaning project.

The bigger diameter water and sewer mains will need more ice slurry, which could affect the cost. (Note that Ice Pigging™ is not suitable for larger sized diameters of more than 24 inches)

Ice slurry is not as good at detecting obstructions, and this could become costly if an obstruction is not dealt with early on. However, usually, if there is a full blockage or a closed valve, an ice pig can detect this kind of obstruction.

Why Is Ice Pigging™ Less Expensive Than Other Pigging Methods?

There are multiple reasons why Ice Pigging™ is less expensive than other pigging methods. Below you will find more information on some of the reasons why this pigging solution is often the preferred choice for municipalities needing to clean water or sewer mains.

Unlike other pigging solutions, Ice Pigging™ uses up to 50% less water which means municipalities pay less on water costs.

With Ice Pigging™, usually, no excavation is needed, so there are no digging costs or need for pipelines to be exposed or dug up (partly because ice pigs cannot get stuck).

Since Ice Pigging™ is the best at removing large amounts of sediment with one procedure, it is usually significantly more cost-effective than other pigging methods.

Ice Pigging™ lowers the chances of structural damage occurring, saving municipalities money as no repairs will need to be undertaken because of the pigging procedure used.

Pipeline Experts: Inspection, Cleaning, Coating & More

Certified solutions for inspection, pre-commissioning, cleaning, internal coating, ice pigging™, mapping, and turnkey pipeline projects—maximizing safety and reliability at every stage.

Get in Touch With an Ice Pigging™ Expert From American Pipeline Solutions Today!

It's evident that Ice Pigging™ is a cost-effective solution for cleaning water and sewer mains. If you would like to learn more about how the Ice Pigging™ process works and how much it would cost, you can speak with us at American Pipeline Solutions. Our company has years of experience completing high-quality Ice Pigging™ projects that are cost-effective. You can contact us here, and we will be in touch.

FAQs:

What is Ice Pigging™ and how does it work?

Ice Pigging™ is a pipeline cleaning method that uses an ice slurry instead of a solid pig. The semi-solid ice mixture is pumped through the line to scour and remove biofilm, sediment, and mineral deposits. As it moves, it conforms to the pipe shape, cleaning effectively without damaging the walls. When complete, the ice simply melts and is flushed away.

How much does Ice Pigging™ cost per linear foot?

The cost of Ice Pigging™ typically ranges between $1.70 and $5.50 per linear foot, depending on factors such as line diameter, condition, and project scope. For comparison, swabbing may cost $5.70–$9.10, and traditional pigging can reach $16–$21 per foot, making Ice Pigging™ one of the most cost-effective options for water and sewer mains.

What factors influence the cost of Ice Pigging™?

Several elements affect pricing — mainly pipe diameter, length, condition, and accessibility. Larger mains require more ice slurry, which increases production and pumping costs. Projects that involve locating blockages, valves, or restricted sections may also cost more due to additional setup and verification procedures.

Is Ice Pigging™ suitable for all types of pipelines?

No. Ice Pigging™ is best suited for pressurized water and sewer force mains. It is not recommended for gravity-fed sewers or pipelines larger than approximately 24 inches in diameter. APS evaluates each system’s configuration to confirm if Ice Pigging™ is the safest and most effective method for that line.

Why is Ice Pigging™ cheaper than traditional pigging?

Ice Pigging™ reduces total project costs by using up to 50% less water, requiring no excavation or pipeline exposure, and minimizing the risk of pigs getting stuck. It can remove large amounts of sediment in a single pass, and it does not cause structural damage — saving municipalities on post-cleaning repairs and downtime.

What kind of debris does Ice Pigging™ remove?

Ice Pigging™ is highly effective for removing biofilm, iron, manganese deposits, and loose sediment. It can also eliminate organic buildup and suspended materials that cause discoloration or reduced flow. However, it cannot remove hard scale, tubercles, or heavy corrosion — those require mechanical or chemical cleaning.

Can Ice Pigging™ delay the need for pipe rehabilitation?

Yes. By removing organic and mineral deposits, Ice Pigging™ can significantly extend the service life of aging water and sewer mains. It restores internal diameter, improves flow, and delays more expensive rehabilitation or replacement projects, making it an excellent maintenance strategy for municipalities.

How long does an Ice Pigging™ project take?

Most Ice Pigging™ projects are completed within a single day, depending on pipeline length and site conditions. Because the process requires minimal setup and cleanup — and no excavation — downtime is much shorter than with traditional pigging or swabbing.

Is Ice Pigging™ environmentally friendly?

Yes. The process uses water, salt, and energy-efficient equipment, leaving behind no chemical waste or abrasive residue. The melted ice slurry is safely flushed and disposed of through standard wastewater systems, making it a sustainable and environmentally responsible cleaning solution.

How can municipalities request an Ice Pigging™ service quote?

Municipalities and utility operators can contact American Pipeline Solutions directly to request a project evaluation and quote. APS provides a detailed cost estimate based on line data, system configuration, and target cleaning outcomes. Contact APS via Cleaning & Conditioning or our contact form for Ice Pigging™ consultation.

How Does Ice Pigging™ Work? Pipe Cleaning Method

Wondering how Ice Pigging™ works? Learn about the Ice Pigging™ procedure from the experts at American Pipeline Solutions today.

Since its development in 2001 by Professor Joe Quarini at the University of Bristol, Ice Pigging™ has transformed how utilities and industries clean pipelines. Unlike traditional methods, which often require heavy equipment, chambers, or chemicals, Ice Pigging™ combines the cleaning strength of a solid pig with the flexibility of a liquid. The result is a powerful, cost-effective, and environmentally friendly pipe cleaning solution that delivers up to 1,000 times more shear force on internal pipe walls than conventional flushing.

Today, municipalities, water companies, and industrial facilities around the world rely on Ice Pigging™ to restore water quality, extend asset life, and improve pumping efficiency — all with minimal downtime and disruption.

But what exactly is Ice Pigging™, and how does the process work in practice? Below, you’ll find a step-by-step guide to the Ice Pigging™ process, along with answers to common questions and insights into why this innovative method is becoming the preferred choice for pipeline cleaning.

What Is Ice Pigging™?

Ice Pigging™ is a pipeline cleaning process that uses a semi-solid ice slurry. This slurry, made of countless small ice crystals suspended in water, forms what is known as the ice pig™.

Unlike traditional mechanical pigs, which are rigid objects, the ice pig behaves like a liquid during insertion but acts like a solid plug once inside the pipe. As it moves, it applies extremely high shear stress to the internal pipe walls, dislodging sediment, biofilm, iron, manganese, and other deposits.

Because the slurry is flexible, it can adapt to bends, diameter changes, and valves without risk of damage or blockage. And if the ice pig ever stops moving, it simply melts, leaving the pipe clear.

Pipeline Experts: Inspection, Cleaning, Coating & More

Certified solutions for inspection, pre-commissioning, cleaning, internal coating, ice pigging™, mapping, and turnkey pipeline projects—maximizing safety and reliability at every stage.

A Step-By-Step Guide To Ice Pigging™: How It Works

Below is a breakdown of how Ice Pigging™ is carried out in real-world applications. Each step is carefully managed to ensure safety, efficiency, and water quality compliance.

Step One: Isolating the Pipeline

Technicians begin by isolating the main pipeline section. This involves closing upstream and downstream valves, as well as any connecting intersections. Once isolated, the ice slurry — delivered via a specialized tanker — is pumped into the system using 2.5” fire hoses connected to hydrant posts.

Step Two: Controlled Injection

As the slurry enters the pipeline, operators carefully monitor both flow and pressure. This ensures the cleaning process is forceful enough to dislodge fouling but safe enough to avoid pipe damage. Once the section is filled, the upstream valve is opened to push the ice pig through the main using system pressure.

Step Three: Cleaning in Action

The ice pig then travels through the pipeline, scraping away accumulated material such as sediment, biofilm, manganese, and iron deposits. These contaminants are carried within the slurry itself and directed to an exit point, where they are discharged into tankers or a sanitary sewer for proper disposal.

Step Four: Flushing and Return to Service

After the ice pig has exited the system, the pipeline is flushed with clean water until both ice remnants and debris are removed. This ensures the pipe meets strict water quality standards. Because the process requires no harsh chemicals, there is no need for disinfection, and the pipeline can be safely returned to service almost immediately.

What Are the Common Reasons for Ice Pigging™?

Now that we have discussed the step-by-step procedure of Ice Pigging™, it's time to look at the common reasons why municipalities choose Ice Pigging™. Have a look below to learn more.

Ice Pigging™ uses a fraction of the water that flushing and conventional pigging does, making it more environmentally friendly.

Ice Pigging™ can be used for decommissioning cleaning when pipework needs to be cleaned of all residue sediment before it is dismantled.

Ice Pigging™ can be completed when a pipe needs to be cleaned because its use will be changed or if a new product will be used in conjunction with the original piping.

Ice Pigging™ is used to aid with asset management by extending the life of a pipeline to ensure capital spent on pipes and pumps is kept to a minimum.

Ice Pigging™ is perfect for removing accumulations of sediment, biofilm, and foreign objects that are affecting water quality. For example, to improve odor, taste, and lower turbidity levels as well as improve chlorine residuals.

Ice Pigging™ can be employed when a major piping overhaul is planned, and a deep clean of a pipe network is required.

Ice Pigging™ is ideal for improving a sewer force main pumping efficiency by reducing back pressure and increasing flows.

Why Do Municipalities and Industries Use Ice Pigging™?

Ice Pigging™ is chosen over other pipe cleaning methods for several compelling reasons:

Water efficiency – requires only a fraction of the water compared to conventional flushing.

Environmental benefits – avoids harsh cleaning chemicals and reduces wastewater volume.

Asset management – extends pipeline life, helping utilities and industries defer costly replacements.

Improved water quality – enhances taste, odor, and chlorine residuals while lowering turbidity levels.

Operational flexibility – can be performed quickly with minimal system downtime.

Hydraulic performance – reduces back pressure, increases flow, and improves pump efficiency.

Change of use cleaning – prepares pipes for new products or operational changes.

Pre-commissioning or de-commissioning – ensures pipelines are free of debris before use or dismantling.

Beyond municipal water networks, Ice Pigging™ is also widely applied in industries where clean, efficient pipe systems are critical:

Food & Beverage – to eliminate product residues and biofilms safely.

Pharmaceutical & Healthcare – for sterile, contamination-free pipelines.

Chemical & Manufacturing – for process line preparation and maintenance.

District Heating & Cooling – to improve energy efficiency and reduce fouling.

How Is Ice Pigging™ Different from Traditional Pigging?

Despite what many might believe, Ice Pigging™ is different from traditional pigging. Unlike traditional pigging, Ice Pigging™ carries much less risk because it is inserted and removed via existing pipeline fittings. There is an increased chance for risk and disruptions to a pipeline with conventional and foam pigging.

For example, there are installation and launching chambers required, and if the pig or swab gets stuck, a team will have to spend time to locate it then reverse the flow to move it back to the launcher or in the worst case dig it up. In contrast, if the ice pig were to get stuck in a pipeline, the ice would simply melt without causing any problems to a pipeline's infrastructure.

Ice Pigging™ is a far less disruptive pipe cleaning method because a pipeline outage will only take a few hours compared to a few days with other pipe cleaning methods. This means water is restored faster with Ice Pigging™. Interestingly, Ice Pigging™ doesn’t require a lengthy chlorination process, so a pipeline can be returned to service immediately after being cleaned.

Pipeline Experts: Inspection, Cleaning, Coating & More

Certified solutions for inspection, pre-commissioning, cleaning, internal coating, ice pigging™, mapping, and turnkey pipeline projects—maximizing safety and reliability at every stage.

What Are the Limitations of Ice Pigging™?

Although highly effective, Ice Pigging™ does have some limitations:

Pipe size restrictions – most effective in pipelines up to 24 inches in diameter.

Sediment hardness – not ideal for removing very hard, calcified deposits.

Distance limits – typically effective for cleaning up to 2.5 miles of 6-inch pipe in a day.

For these reasons, professional evaluation is essential to determine whether Ice Pigging™ is the right solution for a specific project.

Get In Touch With American Pipeline Solutions for Your Ice Pigging™ Needs

Ice Pigging™ is a sophisticated process that requires specialized equipment and expertise. At American Pipeline Solutions, we are the only company in the United States currently offering Ice Pigging™ services. Our team has extensive experience performing this method for municipalities and industries, helping clients improve water quality, extend asset life, and reduce operational costs.

If you’re considering Ice Pigging™ for your pipelines, we’d be happy to discuss your needs. Contact us directly at paul@americapipe.com, or complete our project questionnaire and include supporting maps so we can assess your system in detail.

FAQs: