Unlocking the Benefits of Smart Pigging - The Future of Pipeline Maintenance

Introduction

A. Definition of Smart Pigging:

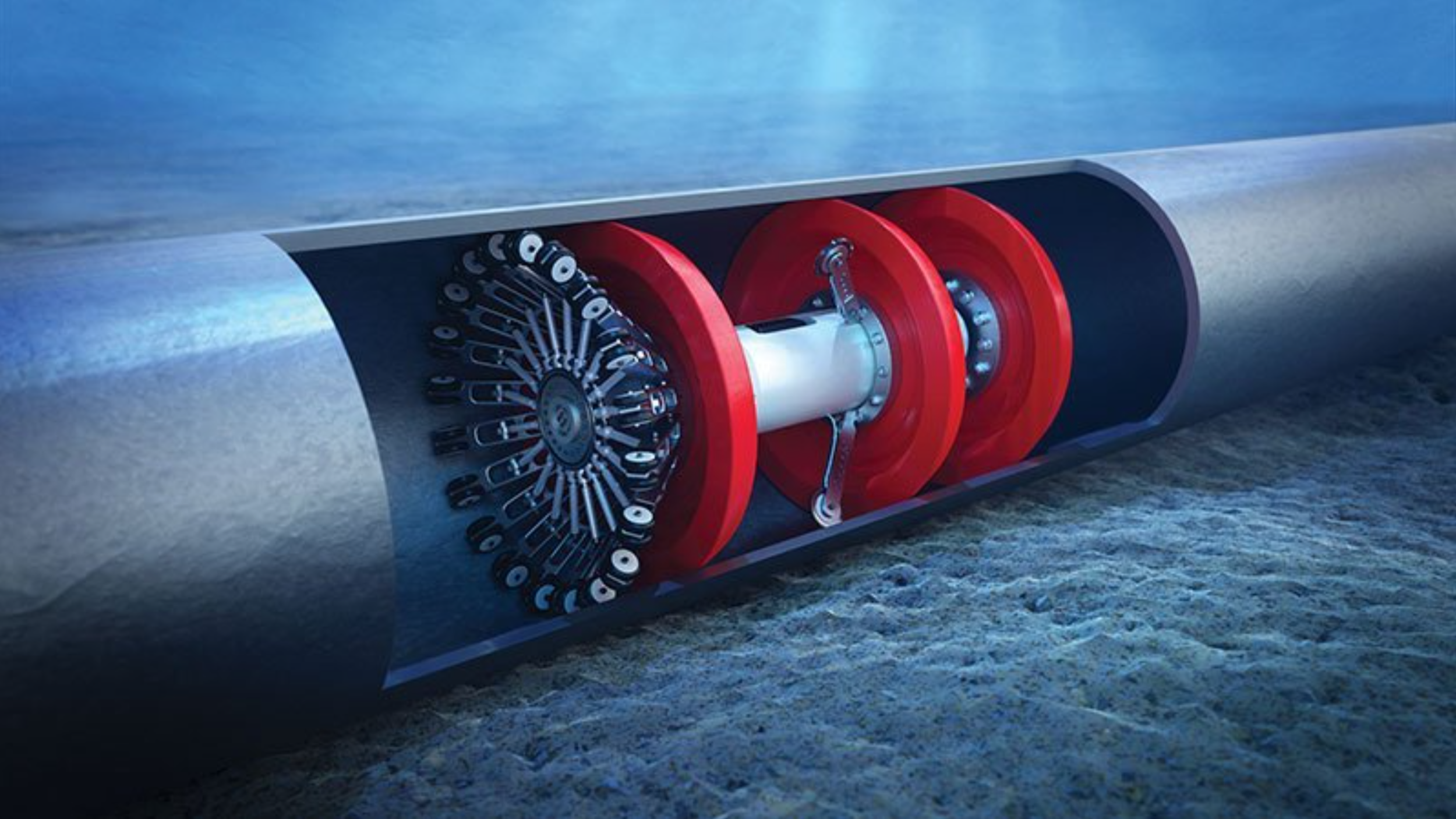

In-line inspection, commonly referred to as “smart pigging,” uses specialized tools known as “smart pigs” to inspect pipelines. The smart pigs move through the pipelines collecting data relevant to their interior condition. This non-invasive process helps ensure the reliability and safety of pipelines. The process also offers an innovative solution to the task of pipeline maintenance.

B. Purpose of the Blog:

Information provided in this blog provides an overview of smart pigging: its technology, applications, and advantages, as well as its limitations.

C. Importance of Pipeline Maintenance:

As critical components of numerous industries ( i.e. oil and gas, water and wastewater, and chemical) pipelines must be properly maintained to ensure longevity, reliability, and safety. Failure to do so risks corrosive damage leading to leaks, spills, and other dangers. By proactively addressing issues thereby preventing costly problems, smart pigging affords users a practical, efficient solution for pipeline maintenance.

Pipeline Experts: Inspection, Cleaning, Coating & More

Certified solutions for inspection, pre-commissioning, cleaning, internal coating, ice pigging™, mapping, and turnkey pipeline projects—maximizing safety and reliability at every stage.

What is Smart Pigging?

A. Technology Overview

Smart pigging technology uses specialized tools to inspect pipeline interiors. These tools are called “pigs.” Equipped with various sensors, pigs detect and measure pipeline conditions such as corrosion, wear, geometry, and wall thickness. The data collected by the pigs is stored and retrieved at the end of the pipeline run. Analysis of the data determines the condition of the pipeline and identifies any potential problems.

B. Types of Pigs

Several different kinds of pigs are used in smart pigging. Each type is designed to serve a specific inspection need. The most common types include magnetic flux leakage pigs, ultrasonic pigs, and caliper pigs.

C. How It Works

The smart pigging process starts by inserting the tool into the pipeline. The flow of the product being transported through the pipeline propels the pig. As it moves through the pipeline, the pig collects data and transmits it to the surface. Once it reaches the end of the pipeline, the pig is removed. The data collected by the pig is analyzed to determine next steps for the proper maintenance of the pipeline.

Advantages of Smart Pigging

A. Cost-Effective

The primary advantage of smart pigging is cost-effectiveness. Because they often require shutting down the pipeline, traditional methods of inspection can be time-consuming and costly. Smart pigging not only can be conducted without interruption of service, but also produces more accurate and detailed data reducing the need for additional follow-up and repairs.

B. Time-Efficient:

Additionally, smart pigging is time efficient. Pigs travel rapidly and without interruption providing quick and accurate assessments of the pipeline’s interior conditions. The company can then make better informed decisions regarding maintenance and repairs leading to less downtime and increased productivity.

C. Increased Safety

Smart pigging inspects pipelines from the inside minimizing the risks of accidents and spills associated with more invasive, traditional techniques. This safer alternative also helps companies identify and address potential hazards more quickly before they become serious problems.

D. Improved Data Collection

The comprehensive data collection provided by smart pigging allows companies to monitor pipeline conditions over time. Information about wall thickness, corrosion, wear, and pipeline geometry enables companies to address maintenance needs in a timely fashion thereby preventing more costly problems.

Applications of Smart Pigging

A. Detection of Corrosion and Wear

Smart pigging is often used to detect corrosion and wear in pipelines. Pigs equipped with magnetic flux leakage or ultrasonic sensors can detect changes in the pipeline’s magnetic field or ultrasonic wave patterns. Such changes can indicate corrosion or other weaknesses in the pipe wall. The pigs’ sensors transmit this data to the surface for further analysis. The results help determine the extent of any damage and next steps for maintenance.

B. Inspection of Pipeline Geometry

For best performance, pipelines must be assessed for any deviations from their original geometry. Using caliper sensors, smart pigs can measure the diameter of the pipeline and detect any deformities and/or distortions. Left unaddressed these deviations can cause increased friction and stress leading to leaks or ruptures.

C. Evaluation of Pipeline Cleanliness

Cleanliness is important for efficiency and safety of pipelines. Smart pigs such as American Pipeline Solutions’ Smart Foam Tool are equipped with sensors to detect debris or build-up impeding the flow of the fluid or gas transported by the pipeline. Evaluating the cleanliness of the pipeline helps protect it from blockages or reduced flow rates.

D. Measurement of Pipeline Wall Thickness

Smart pigs equipped with ultrasonic sensors can measure a pipeline’s wall thickness. This information is critical in determining the structural integrity of the pipeline. Data indicating wear corrosion or compromised wall thickness helps companies more accurately establish the maximum allowable operating pressure (MAOP).

Limitations of Smart Pigging

A. Limitations of Different Types of Pigs

Of course, as with any tool, smart pigging has limitations. For example, some smart tools may be unable to detect corrosion in pipelines made of non-ferromagnetic material. Ultrasonic pigs may have limited ability to identify corrosion in pipelines with thick coatings or heavy scale buildup. Recognizing these limitations is important when choosing the appropriate smart pigging solution for pipeline maintenance.

B. Limitations of Pipeline Configuration

Pipeline configuration also impacts the effectiveness of smart pigging. Pigs may have difficulty navigating pipelines with tight bends or numerous changes in direction. Pipelines with multiple branches or complex configurations may require more than one pig or special equipment to perform the inspection. Most smart pigs require a launcher and receiver to be deployed and recovered.

C. Limitations of Operating Conditions

Operating conditions are another factor affecting the accuracy and reliability of the data collected by this smart tool. High pressure or temperature can interfere with the sensors on the smart pig. Fluid flow and viscosity can impede its movement. Choosing a smart pigging solution requires careful consideration of the pipelines’ operating conditions.

Pipeline Experts: Inspection, Cleaning, Coating & More

Certified solutions for inspection, pre-commissioning, cleaning, internal coating, ice pigging™, mapping, and turnkey pipeline projects—maximizing safety and reliability at every stage.

Smart Pigging in Pipeline Inspection and Diagnostics

Smart pigging plays a critical role in modern pipeline integrity management. It enables operators to inspect pipelines from the inside, without interrupting flow, and provides data that informs both immediate decisions and long-term asset planning. In new pipeline installations, smart pigging establishes a performance baseline, while in older systems, it helps track aging and wear over time.

One of the key advantages is its ability to perform pipeline condition assessments through trend comparisons of successive inspection runs. These comparisons make it possible to detect gradual deterioration, such as increasing corrosion or wall thinning, and address it before it escalates into a major issue.

Smart pigging is also used for pressure pipe inspection, helping operators confirm the Maximum Allowable Operating Pressure (MAOP). By providing accurate internal measurements and identifying anomalies, smart pig data supports regulatory compliance and safe operations.

Another major application is in corrosion monitoring. Smart pigs can detect and track corrosion rates over time, giving operators the ability to assess how quickly corrosion is progressing in different sections of the pipeline.

All this data feeds directly into risk-based maintenance planning. Rather than relying on fixed maintenance schedules, operators can make informed decisions based on quantifiable defect data—prioritizing resources where they are most needed and extending the service life of infrastructure safely.

Industries That Use Smart Pigging

Smart pigging is not limited to a single industry. Its benefits are recognized across a wide range of sectors that depend on pipeline infrastructure for critical operations.

In the oil and gas industry, smart pigging is widely used in both crude and natural gas transmission pipelines. It helps detect early-stage corrosion, metal loss, and geometric deformities that could compromise flow or lead to leaks.

Water utilities employ smart pigs for the inspection of both potable water and wastewater pipelines. These tools allow for non-invasive diagnostics that identify sediment build-up, blockages, and structural issues—all while keeping the water supply operational.

In the chemical processing sector, pipelines often carry corrosive substances under pressure. Smart pigging is essential for monitoring internal conditions, ensuring product purity, and detecting potential leakage points that could lead to safety hazards or environmental violations.

The energy and power industries, especially those involving high-pressure steam or hydrogen delivery, use smart pigs to validate the integrity of their pipelines under extreme conditions. This prevents system failure and ensures continuity in power generation.

Lastly, industrial manufacturing facilities depend on pipeline systems within their plants for efficient operations. Smart pigging helps verify pipeline health, clean internal surfaces, and maintain system reliability across various processes and production lines.

Conclusion

Future of Smart Pigging

Smart pigging is a rapidly evolving technology with a bright future. The demand for efficient, cost-effective pipeline maintenance continues to grow. Smart pigging offers an innovative and reliable solution. Advancements in sensors and data analysis will lead to even greater accuracy, efficiency, and safety of this technology.

Importance of Pipeline Maintenance

Pipeline maintenance is essential to the safe and efficient operation of pipelines. Smart pigging is a powerful tool for achieving this goal. By providing accurate analyses of pipeline conditions, smart pigging enables companies to proactively address issues before they become serious problems.

Final Thoughts

Smart pigging is a powerful and innovative technology changing the way companies approach pipeline maintenance. By providing a more accurate view of pipeline conditions, this smart tool reduces costs, improves efficiency, and increases safety. Clearly, the future is bright for smart pigging as an indispensable component of pipeline maintenance.

Frequently Asked Questions

How often should pipelines be smart pigged?

Run intervals depend on fluid type, operating conditions, and regulations. Annual to biennial runs are common for critical systems; less frequent use is possible for lower-risk lines.

Is smart pigging necessary for all pipelines?

Pipelines transporting hazardous fluids or under high pressure greatly benefit from smart pigging. Newer or low-risk systems may require less frequent inline inspection.

What is the difference between smart pigging and pipe inspection?

Smart pigging is a form of pipe inspection, specifically in-line inspection using specialized tools. It covers more than geometry; smart pigs also collect pressure-related, metal-loss, and corrosion data.