In-Line Pipeline Inspection Using Inspection Balls

Fast condition assessment with minimal setup and small access points

When you need real answers about blockage, internal condition, pressure anomalies, or hydraulic behavior, you don’t always have time, or budget, for major excavations, shutdowns, or complex launch systems. Traditional inspection methods often require significant surface disruption and long planning cycles before you see any meaningful data.

American Pipeline Solutions (APS) offers in-line inspection using multi-parameter inspection balls that move through your live pipeline and collect actionable data in a single intervention. The goal is simple: give utilities and operators clear information about pipeline behavior with as little disruption as possible.

This is a low-impact, highly practical inspection method designed for small insertion points, minimal setup, and real-world operating conditions. It also integrates naturally with APS services like pipeline cleaning, Ice Pigging™, and pipeline inspection / pipeline condition analysis.

What Our Inspection Ball Service Reveals?

An inspection ball run gives you a continuous picture of how your pipeline behaves along its length, not just isolated readings at a few test points. As the tool moves through the line, it captures high-resolution acoustic and pressure information that APS turns into clear, decision-ready insights.

During a typical inspection ball project, APS can help you:

Identify pressure anomalies that may indicate leaks or restrictions

Estimate blockage levels and distribution

Qualitatively evaluate internal material condition

Establish the longitudinal hydraulic profile of the pipeline

This global view of condition helps you decide where to clean, where to dig, and where to invest in rehabilitation, without dismantling assets or taking long sections out of service.

Why Utilities and Operators Choose This Approach

Many utilities and industrial operators come to this service when conventional methods are either too disruptive or too costly for the current need. Our approach is geared toward practical deployment on real systems, not idealized test loops.

Small Access Points, Minimal Surface Disruption

A key advantage of inspection balls is their ability to enter the system through existing openings. In many cases, APS deploys the tool via valves, hydrants, fittings, or other available access points.

Because we often do not need large excavations or permanent launcher installations, this service is especially well suited for urban mains, buried lines under critical infrastructure, and long transmission pipelines where surface disruption must be kept to a minimum.

Lean Setup and Short On-Site Time

Inspection ball deployments are designed to be lean. There is no complex launch or recovery infrastructure to build, and the field footprint is small.

This allows for:

Faster mobilization

Shorter on-site durations

Reduced impact on daily operations and customers

In many cases, we can run the inspection while the system remains in normal operation, or with only minor adjustments to flow.

Works on Live Pipelines Under Real Operating Conditions

Because inspection balls travel with the fluid under operating conditions, the data reflects what the pipeline actually experiences in day-to-day service. You see true hydraulic and acoustic behavior, not an artificial test environment.

This live-line capability makes the service attractive for drinking water, raw water, wastewater, and compatible industrial systems where shutdown is difficult or undesirable.

Long-Distance, System-Level Insight

Rather than focusing on small segments or individual test points, inspection balls can cover multiple kilometers in a single run, generating a continuous condition profile.

That makes them ideal for:

Long transmission mains

Remote segments that are hard to access

Networks where you need a system-level view before committing to major interventions

When to Use Inspection Balls: Before Cleaning, After Cleaning, or Standalone?

One of the strengths of this service is its flexibility. APS can deploy inspection balls at different stages of your asset management program depending on your goals.

Before Cleaning

When performance issues appear, it is not always clear whether the root cause is heavy deposits, hydraulic limitations, or localized anomalies. A pre-cleaning inspection ball run helps clarify the picture.

Before cleaning, operators use this service to:

Differentiate between blockage, hydraulic constraints, and other anomalies

Quantify blockage levels along the pipeline

Highlight specific locations worth verifying or monitoring

Right-size future cleaning scopes instead of guessing

After Cleaning

Following a cleaning campaign—whether through flushing, conventional pigging, or Ice Pigging™—you need to know how effective the work was and whether additional action is required.

After cleaning, inspection balls help you:

Confirm blockage removal and improvement in hydraulic performance

Check for pressure anomalies that may still indicate restrictions or defects

Document internal condition as part of return-to-service protocols

This ties directly into APS’s broader pipeline cleaning and Ice Pigging™ services and closes the loop between intervention and verification.

As a Standalone Condition Assessment

Even without a specific cleaning or rehabilitation project in mind, inspection balls can serve as a fast, low-impact health check.

Operators rely on standalone inspection ball services when they need:

A quick condition assessment of long or remote mains

Data to prioritize lining, replacement, or more detailed inspection

A low-disruption alternative to large investigative digs or capital-intensive inspection campaigns

How APS Inspection Ball Technology Works?

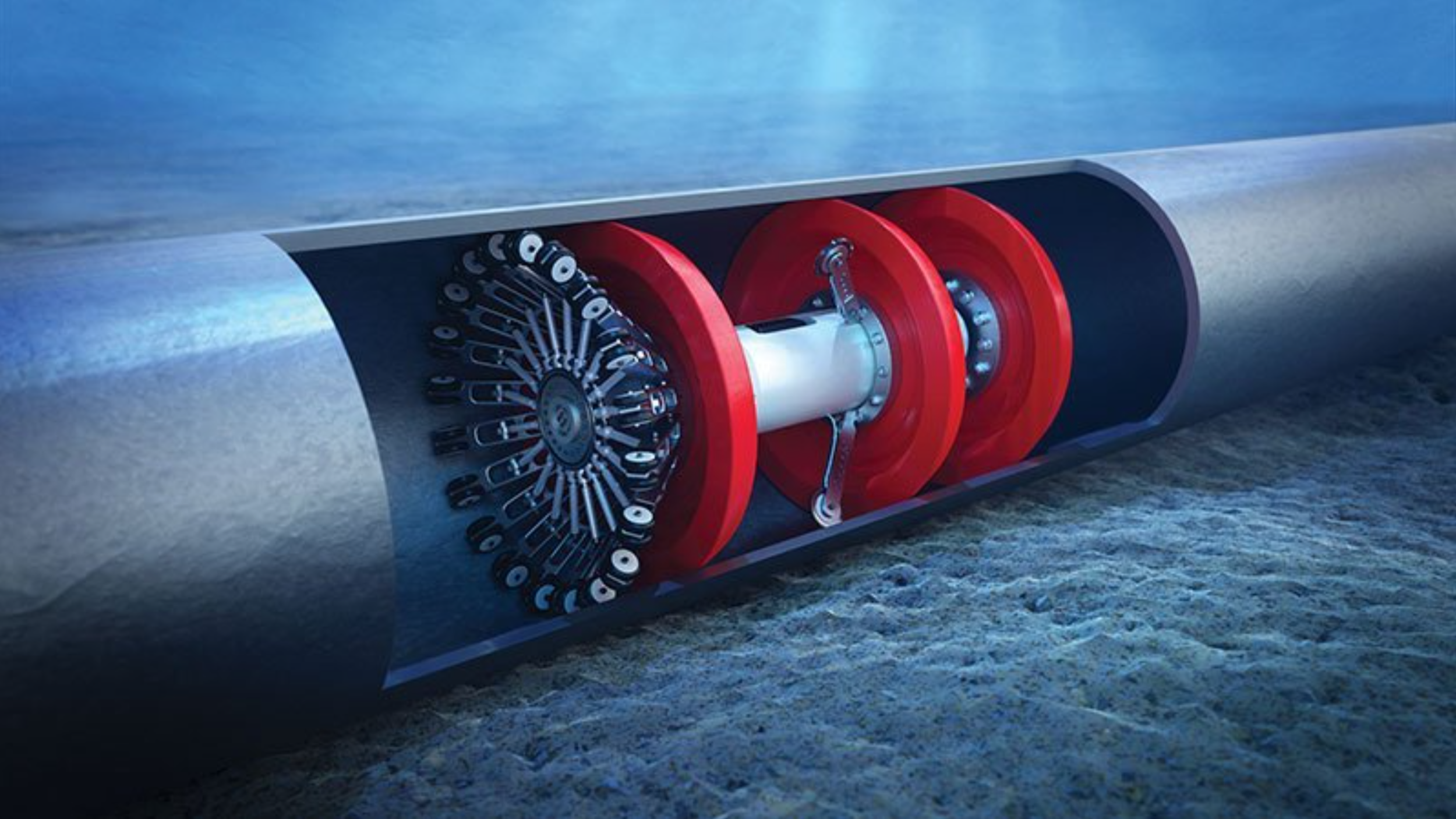

Our in-line inspection balls contain a compact suite of acoustic and pressure sensors. As they move through the pipeline, they continuously record how the system behaves, and APS converts those raw signals into a clear condition assessment.

Acoustic Sensing

The acoustic system listens for sound patterns that indicate unusual behavior. This can include the signature of leaks, turbulence around restrictions, or disturbances caused by structural or geometric irregularities.

By analyzing these acoustic signatures along the route, APS pinpoints sections where something is not behaving as expected, giving you candidates for targeted verification or follow-up inspection.

Pressure Sensing

Alongside acoustic data, high-resolution pressure sensors track how pressure changes along the pipeline. Slow pressure drops, localized losses, and transient events can all be indicators of restrictions, blockages, or hydraulic imbalances.

These measurements support:

Blockage estimation and localization

Evaluation of overall hydraulic performance

Identification of sections where flow behavior suggests internal issues

Multi-Parameter Condition Profile

The true value of the service lies in the combination of acoustic and pressure data. When both signals highlight the same area, confidence in the findings increases significantly.

APS uses this multi-parameter approach to build a global condition profile of your pipeline. This goes beyond what visual inspection or spot testing alone can provide and helps you distinguish between blockage, hydraulic limitations, and potential leak or defect locations.

Systems and Pipe Types We Serve

Inspection balls are designed to be versatile and adaptable within defined operating envelopes. APS evaluates each application individually to ensure that the tool and run parameters match the system.

Typical applications include:

Drinking water transmission and distribution mains

Raw water pipelines and intakes

Wastewater and select industrial systems

District energy networks where conditions are compatible

A range of pipe diameters and materials can be addressed. During the initial review, APS will confirm suitability based on diameter, fluid type, access points, and operating conditions.

How This Service Fits into Your Overall Pipeline Program?

In-line inspection balls are not meant to replace every other inspection method. They are designed to bridge the gap between guesswork and heavy-duty inspection programs.

APS integrates inspection ball results with our other services, including:

Pipeline cleaning and Ice Pigging™ – using condition data to design focused cleaning campaigns

Pipeline inspection / pipeline condition analysis – feeding results into broader integrity assessments

Mapping and planning – tying anomaly locations to your GIS and capital plans

Internal pipe coating and rehabilitation planning – helping prioritize segments for lining or targeted rehabilitation

The result is a service that delivers quick, practical answers now and also informs your long-term asset management strategy.

What You Receive from an APS Inspection Ball Project?

At the end of an inspection ball run, you receive a clear, operator-friendly package of information—not just raw data.

Deliverables typically include:

A concise summary of internal pipe condition and hydraulic behavior

A blockage assessment along the inspected section

An anomaly list with GPS or chainage references (where available)

Operational notes from the run

Optional recommendations for verification, cleaning, or further inspection

You walk away with actionable insight, ready to support decisions on cleaning, rehabilitation, or more detailed inspection.

Frequently Asked Questions About Inspection Ball Services

Do inspection balls require a shutdown?

In many cases, no. Inspection balls are designed to operate under live conditions using existing flow. Some projects may require short-term adjustments, which APS defines during planning, but full shutdowns are often avoided.

What if the inspection ball encounters a tight spot or obstruction?

Before any deployment, APS reviews pipeline geometry, access, and expected conditions to select the right tool and minimize risk. A run plan and contingency measures are developed in advance so the project is controlled and predictable.

Is this a replacement for smart pigging or CCTV?

No. Inspection balls complement other methods. They are ideal for fast, system-level assessment with minimal setup, while smart pigging and CCTV provide more detailed, localized views when required. Often, inspection ball data is used to decide where to focus those more intensive techniques.

How accurate is blockage estimation?

Blockage levels are estimated based on characteristic changes in pressure and acoustic signals. While not a substitute for direct physical measurement, these estimates provide reliable, decision-grade indications of where deposits or restrictions are most significant.

How do I know if my pipeline is a good candidate?

Share your pipe diameter, approximate length, fluid type, and available access points with APS. Our team will assess compatibility and confirm whether in-line inspection ball services are appropriate for your system.

Request In-Line Inspection Ball Services from APS

If you need a fast, low-disruption condition assessment for your pipeline but cannot justify large excavations or complex launch systems, APS in-line inspection ball services may be the right fit.

Provide us with your:

Pipe diameter

Approximate length

Fluid type

Available access points

And American Pipeline Solutions will confirm feasibility, outline a deployment plan, and show how this service can support your cleaning, verification, and long-term rehabilitation decisions.