inline inspection

Modern pipelines carry critical products through cities, plants, and remote landscapes every day. Knowing what is happening inside those lines is essential for safety, reliability, and long-term performance. Inline inspection—sometimes called intelligent pigging or ILI—is one of the most powerful tools operators have to understand pipeline conditions from the inside out.

At American Pipeline Solutions (APS), inline pipeline inspection is a core part of how we help clients protect their assets. We combine smart pig technology with cleaning, mapping, and condition analysis to deliver clear, actionable information about corrosion, deformation, and other threats. Rather than just running tools, we provide integrated inline inspection services that fit into your broader integrity management program.

What Is Inline Pipeline Inspection (ILI)?

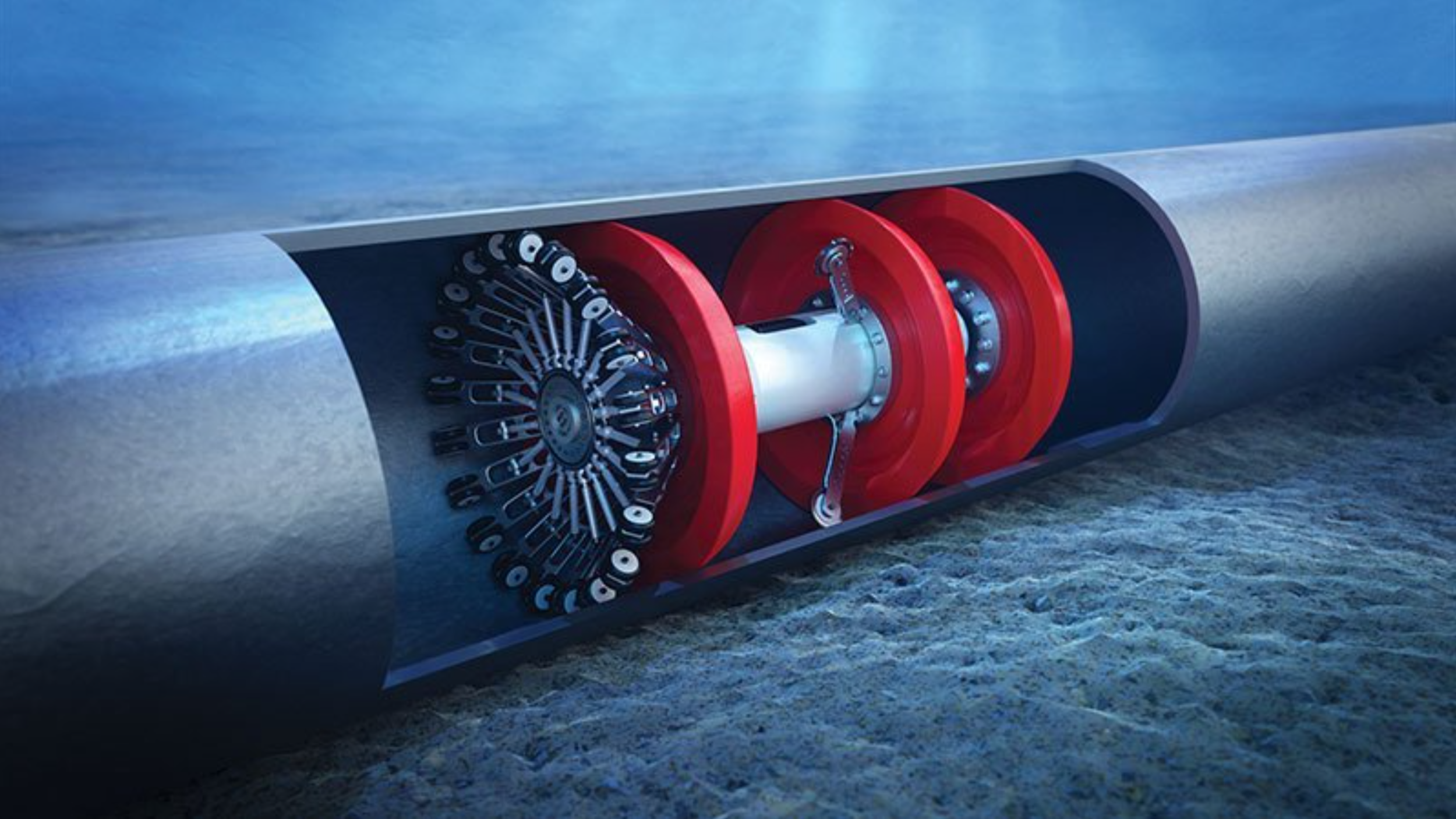

Inline pipeline inspection is the process of running sensor-equipped tools, or “smart pigs,” through a pipeline while it is in service or under controlled conditions. These tools travel with the product flow or under pressure, continuously measuring the pipe wall and geometry as they go.

Unlike external inspections or hydrostatic tests, inline inspection looks at the pipeline from the inside and records detailed data along every foot of the route. It can be used to establish a baseline for new pipelines, to carry out periodic integrity assessments, or to support life-extension and change-of-service projects.

Inline pipeline inspection helps you answer critical questions:

Where is corrosion occurring, and how severe is it?

Are there dents, buckles, or ovalities that could affect future performance?

Has the pipeline shifted, settled, or experienced strain?

APS works with operators to plan and execute pipeline inline inspection programs that provide reliable answers to these questions and support better decision-making.

What Inline Inspection Services Detect?

Inline inspection services provide much more than a simple “pass/fail.” They deliver detailed information about the condition of your pipeline, allowing you to identify and prioritize specific threats.

Corrosion and Metal Loss

One of the primary goals of inline inspection is to identify and size metal loss. Intelligent pigs equipped with Magnetic Flux Leakage (MFL) or ultrasonic sensors can detect internal and external corrosion, pitting, and general wall thinning. This information is used to calculate remaining wall thickness and assess whether the pipeline can safely continue operating at its current pressure.

Cracks, Weld Issues, and Seam Threats

Certain inline inspection tools are designed to detect cracking, seam-related threats, and weld defects. These may include long seam weld anomalies, girth weld issues, or localized cracking that develops over time. Identifying these features early allows operators to plan targeted digs and repairs before they become serious integrity concerns.

Dents, Geometry, and Deformation

Geometry and caliper tools focus on the shape of the pipeline. They measure dents, ovalities, buckles, misalignments, and other deformation features that can create local stress concentrations. Inline inspection provides precise information on the depth, length, and orientation of these anomalies so you can understand how they affect the pipe’s ability to carry pressure over time.

Route, Strain, and Movement

Many inline inspection tools include Inertial Measurement Units (IMUs) that track the pig’s movement as it travels. This data is used to create highly accurate centerline maps, identify bends, and detect potential ground movement or strain. When combined with APS’s mapping services, IMU data helps pinpoint where external threats—such as landslides, subsidence, or third-party activity—may be affecting your pipeline.

APS Inline Inspection Capabilities

APS provides inline inspection services as part of a broader pipeline integrity offering. We understand that no two pipelines are the same, and that each inline inspection project needs to consider geometry, product, flow, and access.

Smart Pigs and Advanced Sensors

Through our inline inspection programs, APS works with a range of smart pig technologies to match the right tool to your pipeline. These may include:

MFL tools for identifying and sizing metal loss.

Ultrasonic tools for detailed wall thickness measurements.

Geometry and caliper tools for dents, buckles, and shape issues.

IMU-equipped tools for mapping, bend detection, and strain assessment.

We integrate inline inspection results directly into our Pipeline Inspection / Pipeline Condition Analysis services, turning raw data into clear information about your pipeline’s health.

Inline Inspection Across Pipeline Types

APS supports inline pipeline inspection on a wide range of systems, including oil and gas transmission lines, water and force mains, and industrial pipelines where pigging is feasible. Our experience with cleaning, pre-commissioning, and difficult-to-inspect lines makes us a strong partner for pipelines that don’t fit a perfect textbook profile.

Whether you operate a long-distance transmission line or a complex facility network, APS can help you determine how inline inspection fits into your integrity strategy.

Our Inline Pipeline Inspection Process

Successful inline inspection is never just about the tool. It is about planning, preparation, execution, and analysis. APS follows a structured process that reflects industry best practices and our own field experience.

Engineering Review and Feasibility

Every project begins with an engineering review. APS gathers and evaluates available information, including as-built drawings, operating envelopes, pigging history, and previous inspection reports. We confirm key parameters such as diameter, wall thickness, product type, flow and pressure ranges, and existing launcher/receiver configurations.

This feasibility step helps determine whether the pipeline is ready for inline inspection as-is, or whether cleaning, modifications, or other preparation is needed.

Pipeline Cleaning and Pre-Inspection Preparation

Cleanliness and piggability are central to inline inspection. Before running smart pigs, APS designs and executes a Pipeline Cleaning program tailored to your line. This may include foam pigs, brush pigs, and other cleaning tools to remove debris, wax, or scale that could interfere with inspection data or tool passage.

For water and force mains, APS can incorporate Ice Pigging™, an advanced cleaning method that uses ice slurry to remove deposits and biofilms without damaging the pipe.

In new or modified pipelines, these preparation steps can be integrated with Pipeline Pre-Commissioning so that drying, cleaning, and initial inline inspection occur in a coordinated sequence.

Inline Inspection Run Execution

Once the pipeline is prepared, APS supports the planning and execution of the inline inspection run itself. We help select the appropriate tool configuration—whether that is MFL, ultrasonic, geometry, or a combination—and ensure that launching and receiving activities are safely managed.

During the run, we monitor tool speed, pressure conditions, and tracking data to confirm that the inspection is proceeding as expected. The goal is to achieve full coverage of the target pipeline section with high-quality data that can be confidently interpreted.

Data Analysis and Pipeline Condition Reporting

After the run, the real work begins. APS’s Pipeline Inspection / Pipeline Condition Analysis services interpret inline inspection results in the context of your pipeline’s design, operation, and history. We review reported features, validate anomalies, and identify the defects that matter most to safety and integrity.

The outcome is not just a data dump. APS provides condition summaries, feature listings, and clear recommendations that you can use to prioritize repairs, recoating, or internal mitigation.

Integrity Planning and Follow-Up Services

Inline inspection is most effective when its results feed into a broader integrity plan. APS helps translate ILI data into targeted dig programs, internal repair strategies, or coating and internal pipe coating solutions designed to extend remaining life.

Where appropriate, inline inspection results can also support decisions about hydrostatic testing, nitrogen testing, or moderate pressure adjustments. Our goal is to ensure that each inspection leads to concrete steps that improve pipeline performance and reduce risk.

Inline Inspection vs Other Inspection and Testing Methods

Inline inspection is a powerful tool, but it is not the only tool. APS helps clients understand how ILI fits alongside other methods so they can choose the right combination for each pipeline.

Inline Inspection vs Hydrostatic Testing

Hydrostatic testing confirms that a pipeline can hold a specific pressure without leaking or failing. It is useful for commissioning and revalidation, but it does not reveal the size, location, or type of defects that exist in the pipe wall.

Inline inspection, on the other hand, provides defect-level information across the length of the pipeline. It can show where metal loss is occurring, how deep defects are, and how close they are to interacting with other features. When used together, hydrotesting and inline inspection provide both proof of strength and insight into underlying condition.

Inline Inspection vs External NDE and Direct Assessment

External non-destructive examination (NDE), close-interval surveys, and direct assessment approaches are important tools for pipelines that cannot be pigged. They focus on external factors such as coating condition, cathodic protection performance, and local wall thickness measurements.

When a line is piggable, inline inspection delivers a much more complete internal picture. APS helps operators decide when to rely on external methods and when inline inspection is the better option, especially for long, buried segments where access is limited.

Combining ILI with Cleaning, Coating, and Mapping

Inline inspection data is most valuable when it is integrated with cleaning, internal coating, and mapping. Clean pipelines improve inspection quality. Mapping helps translate inspection findings to precise locations in the field. Internal coating, applied after repairs and cleaning, can help slow corrosion and protect metal in known risk areas.

APS delivers all of these services under one roof, making it easier to move from inspection to action without losing time or information.

Why Inline Pipeline Inspection Matters for Integrity Management?

Inline inspection services play a central role in modern integrity management. They help operators demonstrate that their pipelines are fit for service, support regulatory compliance, and reduce the likelihood of leaks or failures.

By identifying corrosion, deformation, and other defects before they progress too far, inline inspection allows for planned, controlled repairs instead of emergency response. It also supports more accurate remaining life assessments and MAOP evaluations.

Ultimately, inline inspection provides confidence—confidence that your understanding of pipeline condition matches reality, and that your maintenance program is targeting the right areas.

Choosing Inline Inspection Companies: Why APS

There are many inline inspection companies and tool providers in the market. APS distinguishes itself by focusing on integration and practical outcomes rather than just the inspection run itself.

We bring together inline inspection, Pipeline Cleaning, Ice Pigging™, Pipeline Pre-Commissioning, Pipeline Inspection / Pipeline Condition Analysis, internal coating, and mapping under a single service umbrella. That means you get a coordinated program from preparation through analysis, not a series of disconnected activities.

APS also has extensive experience with challenging and previously “unpiggable” pipelines. We understand how to work with difficult geometries, low-flow conditions, and legacy systems that require careful planning and staged improvements before they can be inspected inline.

Our reporting emphasizes clarity and practicality. Instead of leaving you with complex data alone, we focus on providing prioritized recommendations and supporting your team as you move from findings to field action.

If you are evaluating pipeline inline inspection companies or planning your next integrity assessment, APS is ready to help you design and execute a program that fits your assets, your operations, and your regulatory environment.

Inline Inspection Services FAQs

What is inline pipeline inspection and how does it work?

Inline pipeline inspection uses smart pigs—instrumented tools that travel inside the pipeline—to measure wall thickness, detect corrosion and deformation, and map the pipeline route. The pig moves with the product flow or under pressure and records data continuously along the length of the line.

What defects can inline inspection detect?

Depending on the tool configuration, inline inspection can detect internal and external corrosion, pitting, general wall loss, dents, buckles, ovalities, misalignments, certain types of cracking, and weld-related anomalies.

Do I need to clean my pipeline before inline inspection?

In most cases, yes. Cleaning improves tool passage and ensures that sensors are in contact with the pipe wall. APS designs cleaning programs—including conventional pigs and Ice Pigging™ where appropriate—to prepare pipelines for inspection.

What types of pipelines can be inspected inline?

Inline inspection is commonly used for oil and gas transmission lines, refined product lines, water and force mains, and other pipelines that have suitable geometry, flow, and access for pigging. APS works with clients to evaluate whether a particular line is a good candidate.

How often should inline inspection be performed?

The appropriate inspection interval depends on factors such as pipe age, materials, operating conditions, corrosion history, and regulatory requirements. Inline inspection results are often used to set or refine future inspection intervals as part of an operator’s integrity management plan.

What makes APS different from other inline inspection companies?

APS combines inline inspection with cleaning, Ice Pigging™, pre-commissioning, condition analysis, internal coating, and mapping. This integrated approach turns inspection data into clear, actionable integrity plans instead of isolated reports.